CNC machining processes have become better known to people in manufacturing and elsewhere in recent years. A quick explainer, for anyone who isn’t familiar with the process, is that CNC (Computer Numerical Control) machining is used to communicate digital designs into action, using computer files as guides for machines to cut and sculpt objects to exact specifications. There’s more complexity to it, but that explains the basic concept.

By now, again, the process has become better understood, and the basic benefits are clear. We posted an article about buying reconditioned CNC machines that spoke to some of these basic benefits, pointing out that they can amplify the productivity and profitability of a business and streamline manufacturing. As CNC machining is used more and more though, some additional benefits that tend to fly under the radar are becoming clear.

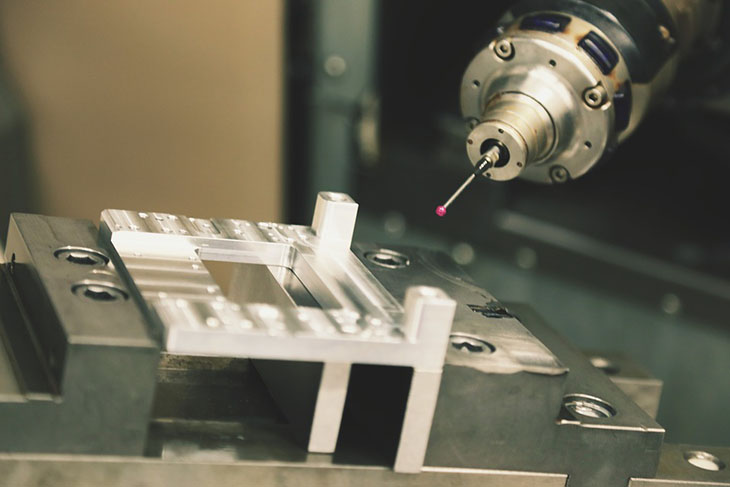

Complex Design

While we know that CNC machining can speed up and improve production, we don’t always tend to think of it as expanding the potential of production. Furthermore, most of the examples we tend to see of CNC-related products are simple - impressive and exact, but relatively straightforward in design (gears, small auto parts, cabinet doors, and the like). What’s become clear, however, is that CNC machining is capable of producing far more complex design than we see in these popular examples. Particularly where 5-axis machining is concerned, this process can now render curved surfaces and more intricate designs on the whole, which expands the potential of the entire method.

Simplified Prototype Evaluation

Much of the focus on CNC machining concerns its ability to produce a mass quantity of products with unbeatable efficiency. Indeed, creating a product line through this process can be far quicker than doing so through more ordinary manufacturing processes. However, the ability for CNC machines to craft individual products or prototypes is also significant, and does tend to fly under the radar. Per Fictiv’s overview of CNC machining services, quotes for projects can be obtained in minutes and parts delivered in days, which can vastly speed up the process for anyone seeking to build and evaluate a prototype. With various specific machining practices available (milling, turning, and so on), up-front price quoting, and quick production turnaround, anyone considering CNC machining can give it a quick test run first.

Improved Environmental Practice

With so much focus on what CNC machining can build and how it can do so, it can be easy to overlook one of the most important concerns about manufacturing in general, which is how it impacts the environment. The Conservation Institute in a piece on industrial pollution identified unplanned growth, outdated technology, and improper disposal of waste as some of the main factors that harm our environment, and the truth is that CNC machining has the potential to bring about positive change in all of these areas. While the process is not yet used as responsibly as it should be in every case, it can help manufacturing businesses to scale only as needed, to generate less waste, and to use technology as a means of making a whole supply chain operate more efficiently - all of which may be good for the environment.

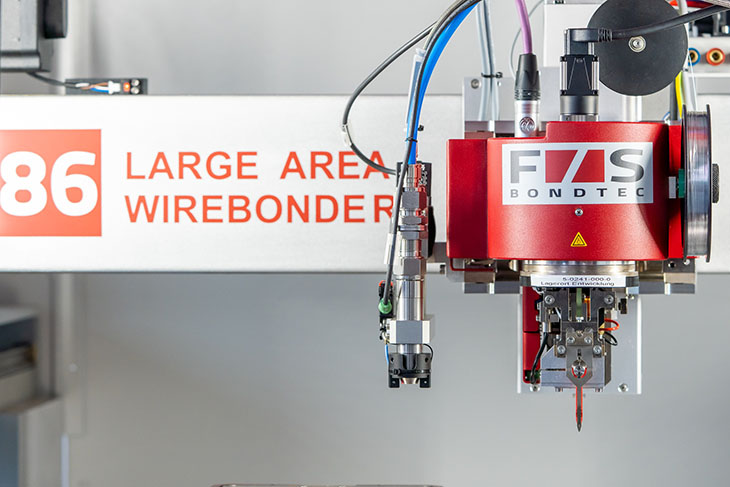

Remote Production

Part of that last point - using technology to make a whole supply chain more efficient - is related to the idea that CNC machining can improve creative and manufacturing processes across distance. Traditionally, a company might not have a whole lot of flexibility once it sets up an ordinary manufacturing business. But with CNC machining, designs can be sent out or outsourced to a related production facility according to the needs of a given project. If a business needs parts delivered across the country, that is, that business might simply be able to have the parts crafted at or near their ultimate destination, as opposed to at a standard manufacturing plant from which they’d need to be shipped. It’s simply a more flexible process, which can have a very positive effect on supply chains.

Really, the basic capabilities of CNC machining are enough to impress, and they’re enough to get a lot of modern businesses and entrepreneurs interested. When you consider these additional perks, however, you can begin to understand why some believe this technology has only just begun to change the manufacturing landscape.