/INS. Following on from the recent investment in a new dilution headbox at BM3, Pankaboard’s investment programme has continued, with an upgrade on their BM2 machine, which produces Folding Boxboards, specializing in the heavier weight substances.

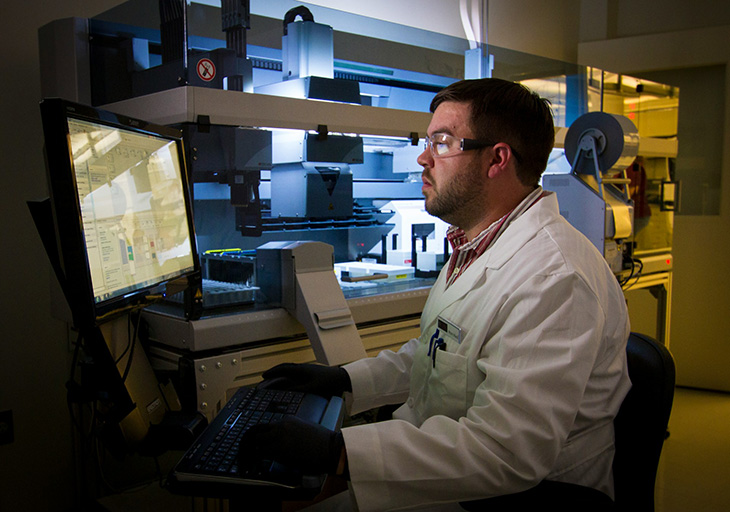

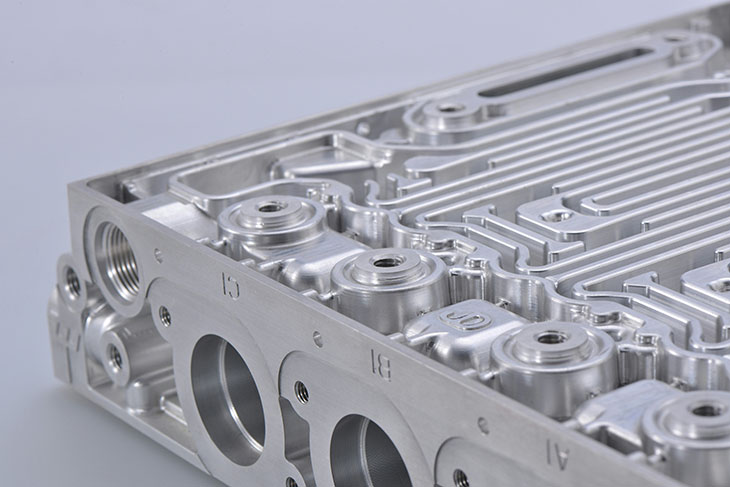

In early 2016 the company made a significant investment to up-grade the formation control on BM2 to meet the highest of quality standards. As a result of this new investment the fiber distribution was reengineered and optimized for enhanced smoothness and converting performance.

“Through this targeted investment and dedicated product development we have been able to reach a superior formation that results in several benefits for our customers” says, Petri Saastamoinen, mill manager at Pankaboard.

The result of the development can be seen as outstanding printing quality, an improved surface for lamination, and improved runnability at high speed packaging lines.

The new fiber technology will enable the company to continue the development work in FBB to further optimize the product offering for strategic end uses.

Pankaboard is a global leading producer of special cartonboards with a capacity of 110 000 t/a. The product portfolio consists of high thickness FBB as well as various uncoated speciality boards. The company serves a wide range of end uses, including luxury beverage and food packaging, picture framing, capseals and visual communication.

Further information:

Petri Saastamoinen

Mill manager

This email address is being protected from spambots. You need JavaScript enabled to view it.

+358-40-526 2871

Christer Nordman

Head of product development

This email address is being protected from spambots. You need JavaScript enabled to view it.

+358-40-8396900