Steel springs are... everywhere, really. Nearly all machines need them. In some cases, they are even a vital part of architecture. Anti-earthquake systems use such elements, for example. To make modern engineering reliable, however, sets of good quality spring sheets are required. Shall we shed a bit of light on the subject?

Heavy-duty spring sheets

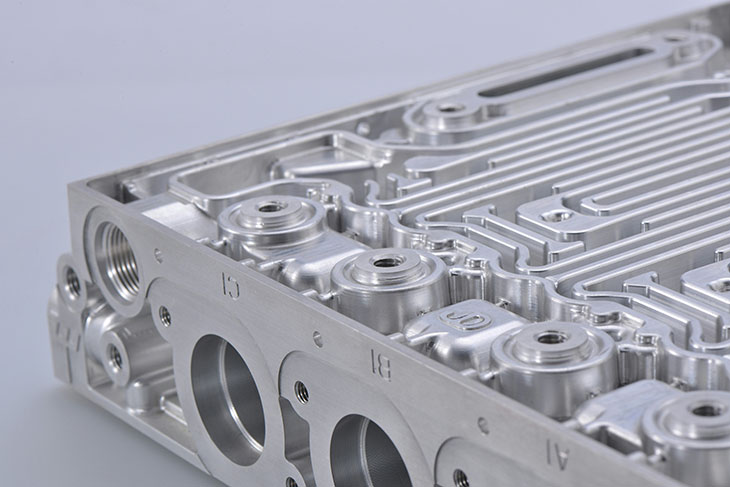

The first thing to know about reliable spring sheets is a fact that they have to have much more properties than any ordinary alloy sheet set. It needs to be super soft in order to change its shape under stress. At the same time, springs must remain extremely resistant to mechanical tension. Because of the way alloy springs work, they also have to return to their original shape and size over and over again, only to continue their exposure to the heavy-duty environment for years to come. A corrosion resistance is an additional quality, although not every grade can offer that.

How to choose a steel grade for springs? All depends upon specific needs. Today, a professional steel manufacturer has many grades to offer. All of them have different properties. 1H18N9 steels are excellent for anti-corrosive spring sheets. PN-71/H-86022 might be better if resistance to heat is a primary factor. The right choice can determine the usability of alloy springs as well as their lifespan.

Carbon spring steel

There's a lot of talk about carbon in modern-day machinery. That material can't be fitted everywhere, though. According to professionals, a carbon steel for spring production is usually implemented in less demanding conditions. Such spring sheets are therefore used for smaller elements that are to be working when the environment temperature doesn't go higher than 150 ℃.

A carbon spring steel can be provided in a form of cold-rolled stripes, bars or even spring wires. Such wires can be incredibly thin or quite thick – depending on customers' requirements. Spring steel in this form is known for surface smoothness and relatively high strength due to different production processes. A controlled heat treatment, for example.

Steel for spring production is a crucial factor. Whether it's carbon, alloy or a mixture of chromium, vanadium and manganese – the right choice of spring sheets will significantly influence the properties of final products. The form in which such sheets are bought also matters. Careful consideration is therefore a must if industrial springs are supposed to be reliable in certain conditions.