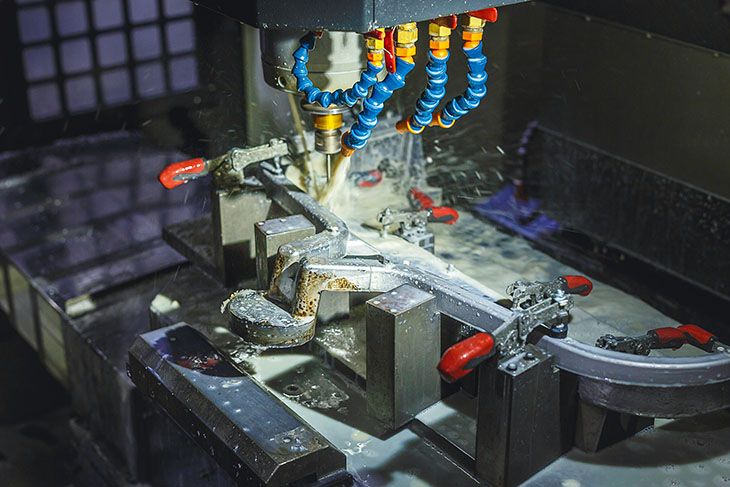

An increasing number of today’s goods are on the millimeter scale. The demand for these products necessitates a micromanufacturing process, whereby companies have specialized equipment, procedures and trained workers to create products to exact specifications.

A less common micromanufacturing definition refers to creating products in small batches, typically to allow companies to meet specific needs and scale more quickly than they otherwise could. Investing in these areas will help companies stay resilient and prepare for the future.

1. Micromanufacturing Enables Efficiency at Scale

Modern decision-makers frequently explore ways to increase how quickly and accurately they can produce in-demand products. Succeeding in these areas can boost competitiveness and help companies scale up as marketplace trends require.

Factories that already have equipment to support the micromanufacturing process can adopt new methods earlier than others.

Much research in this area centers on improving the manufacturing of tech devices ranging from smartphones to virtual reality headsets. In one example, a team developed a new method of picking up and moving micrometer semiconductors in single rolls with high accuracy. Experiments showed this method could simultaneously transfer over 75,000 components from substrates per attempt. Those results are substantial, especially since many large micro-LED screens may have millions of tiny LEDs.

The technique involves a continuous roller-printing process that can match a device’s layout with an accuracy of less than one micron. Scientists reported this approach is low-cost and straightforward enough to reproduce in manufacturing environments with limited resources. Additionally, the researcher believes this method could easily be applied to other products, such as wearable electronics or smart packaging.

2. Micromanufacturing Supports Health Care Advances

Micromanufacturing definitions encompass products less than 10 millimeters large with tolerance ranges of 0.1 to 10 micrometers. People researching health care improvements are particularly interested in such tiny innovations and how they might complement other work.

For example, some researchers think antibody-drug conjugates could be the solution for helping cancer patients get effective treatment without experiencing the side effects when chemotherapy affects healthy cells as well as cancerous ones.

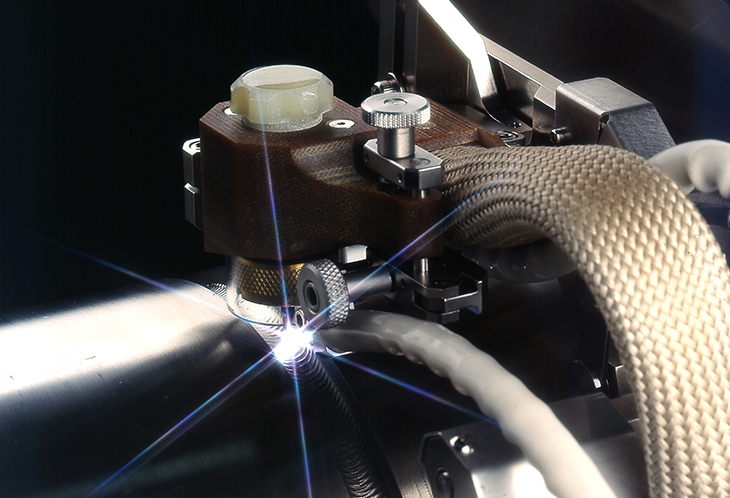

Some researchers are taking a similarly targeted approach with microrobots that go directly to the correct places in the human body to administer therapeutics. In one recent example, a Technical University of Munich team developed a microbot that can move between cell groups to treat individual cells.

The researchers designed the 30-micrometer innovation to respond to human-controlled signals. A person could operate the microbot by steering it directly to a cell and cause the invention to change its temperature and elicit a cellular response. Experiments also suggested the micromanufacturing process for this robot could produce up to 10,000 of the devices per production run. If such metrics remain valid in the real world, they could substantially change cancer treatment and results.

3. Micromanufacturing Enables a Greener Future

Scientists, world leaders and others have warned that people must start making collective changes to protect the planet. A well-developed micromanufacturing process can help, particularly if makers and their clients can reduce waste with right-sized production runs. Some companies may even connect manufacturing requests to real-time customer demand or order data to further reduce the chances of having too many products that won’t sell.

Other opportunities exist, too. Consider an example where researchers from the University of Ottawa devised a micromanufacturing process to create the first micrometer-scale back-contact photovoltaic cells. Tests showed they may lower energy costs by three times compared to conventional options.

These cells are about twice as thick as a human hair strand. Researchers see abundant potential for using them in future goods, such as Internet of Things sensors and miniaturized devices.

Some of the discoveries made through this work could also support other sustainable options, such as energy harvesting or wireless charging products. Items that never need battery changes or only require them occasionally could cut down on waste from discarded power sources.

In one case, researchers developed a brain implant equipped with micrometer LEDs that could deliver light stimulation treatments or drugs. The team enabled it to wirelessly recharge outside the body with an energy harvester.

Those involved were particularly excited by how this improvement could reduce or eliminate surgeries typically required by those with battery-operated internal medical devices. They anticipated using similar technology with products such as pacemakers. If this micromanufacturing process works, patients could use them longer without enduring periodic operations.

Is a Micromanufacturing Process Right for You?

Some micromanufacturing efforts remain in the early stages. However, it’s easy to see their potential in health care, consumer electronics and more. People who stay open to microscale manufacturing will put their organizations in great positions to meet future needs and evolve as new devices and technologies reach the market. Micromanufacturing requires specific investments, but they may be worthwhile, depending on your market and current products.