Abrasive blasting or sandblasting is a popular method for surface preparation. It involves shooting pressurized air or water mixed with abrasive materials at rough surfaces to smooth and clean them. This process is central to achieving proper adhesion and coating effectiveness.

However, there are hazards associated with abrasive blasting. It falls on employers and facility managers to find a way to achieve its economic benefits without compromising worker safety.

The Basics of Abrasive Blasting

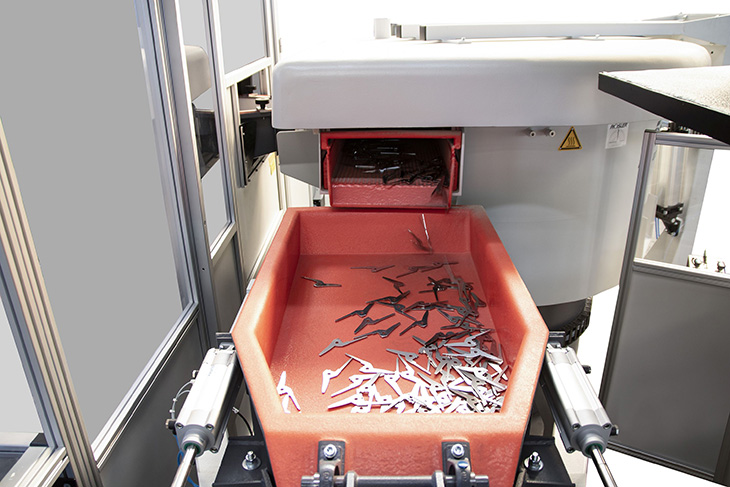

Initially, the abrasive material of choice was silica sand, but other materials such as steel shot, glass beads and aluminum oxide are used today. Some of the most common uses of abrasive blasting include stripping paint from buildings and vehicles, smoothing rough surfaces, and roughing smooth surfaces. Regardless of the material used, the process typically produces large amounts of dust, hence the need for proper safety measures.

What Are the Hazards Associated With Abrasive Blasting?

The blasting process pulverizes the abrasives, coatings and encrusted particles on the underlying substrate. As a result, the dust formed might contain toxic substances that pose health hazards when inhaled.

For instance, inhaling silica sand particles for extended periods can cause a respiratory disease called silicosis. Other potential health issues include possible hearing loss from prolonged exposure to loud blasting machines and eye irritation from the abrasive dust.

Improving Efficiency in Abrasive Blasting Equipment

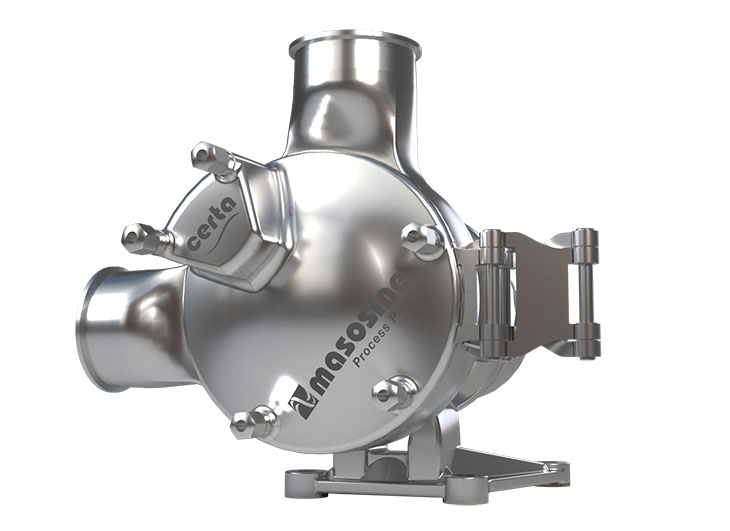

A simple way to measure the efficiency of a blasting setup is by determining how much area it can cover in a given period and the amount of abrasive materials required. Measuring efficiency this way provides valuable insight into what aspects of the equipment may need upgrading or outright replacement.

Of course, this approach assumes the blasting equipment is set up correctly in the first place. The main variables that affect a standard blasting system’s efficiency are as follows.

-

Air Pressure

Lower air pressure means lower output. The optimal air pressure for abrasive blasting is at least 100 pounds per square inch.

Keep in mind the air pressure at the nozzle is not the same as the one from the compressor. This is due to dynamic pressure loss — the inevitable drop in pressure as air travels from the compressor to the nozzle. Dynamic pressure loss is higher in blasting machines with long hose lengths.

-

Air Quality

Air quality relates to the humidity levels at the time of blasting. Humid air in dry blasting can cause the abrasive to become wet, resulting in uneven flow. It can also lead to condensation on blasting equipment and cause flash rust.

-

Abrasive Material

Harder abrasives such as silicon carbide and crushed walnut shells are generally more effective at stripping previous coatings off a surface. Using these might improve efficiency.

It’s important to check the metering valve to ensure optimal abrasive supply to the nozzle. Too many abrasives in the airstream can reduce velocity, while too few can create incomplete blast patterns. Both instances impact productivity.

-

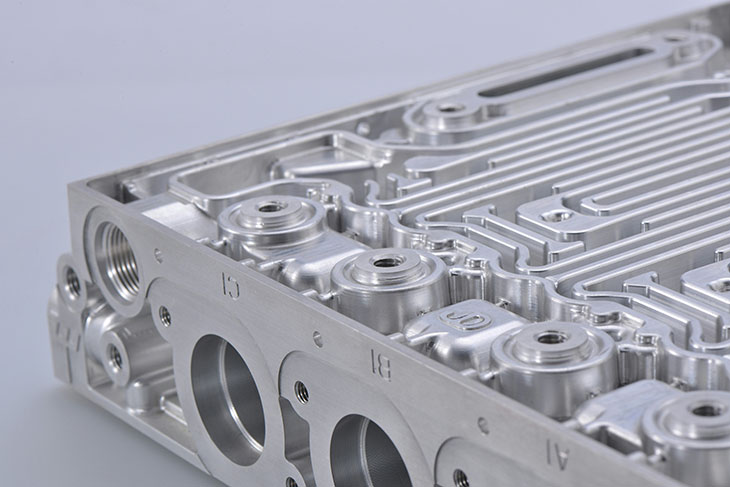

Hose and Nozzle Dimensions

The hose diameter and the nozzle size impact the blasting operation efficiency. A wider diameter means less friction to impede airflow. Similarly, a larger nozzle bore covers a bigger blast area, allowing the worker to do the job quicker.

-

Equipment Condition

The condition of the blasting equipment can also impact its efficiency. For example, newer hoses tend to hold their shape better, allowing air to flow more freely than old, dented hoses that can cause irregular airflow.

Best Practices for Safe Abrasive Blasting

The Occupational Safety and Health Administration provides safety guidelines and best practices for abrasive blasting operations. In addition to following these recommendations, employers and facility managers can protect workers through:

- Education and training: Workers should be fully trained on proper equipment usage and protocols in abrasive blasting.

- Proper protective equipment (PPE): Workers should always be required to put on PPE — face masks, respirators, boots, coveralls and more — when accessing sandblasting areas.

- Wet blasting: This process can reduce the amount of dust from sandblasting. However, it’s not ideal for surfaces susceptible to water damage.

- Dust filter replacements: Cleaning dust filters can degrade the material. It makes more sense to replace the filters when clogged.

- Proper blasting equipment storage: This involves preventive maintenance and keeping blasting environments clean.

Combining Safety and Efficiency for Optimal Abrasive Blasting

Efficiency and safety in abrasive blasting go hand in hand. One exists because the other does.

Striking a balance requires a keen understanding of using equipment correctly while adhering to industry-standard safety measures.