Ball-bearing drawer slides are the unsung heroes of the industrial world, enabling smooth and efficient access to tools, components and more. However, they’re not immune to wear and tear, often requiring attention to keep them running smoothly. Understanding quick and efficient repair methods is crucial for minimizing downtime and maintaining optimal workflow.

Common Issues and Their Symptoms

Misalignment can result from frequent use or improper installation. It typically appears as uneven gaps between the drawer and cabinet, or a drawer that doesn’t close fully. It affects the slide’s effectiveness and can lead to additional wear on other components.

Wear and tear can be insidious, developing over time due to constant loading and unloading of the drawer. It can manifest as a gradual decline in the drawer’s load-bearing capacity, often indicated by sagging or rattling.

Optimizing Ball-Bearing Drawing Slide Performance

You’re familiar with the importance of ball-bearing drawer slides in your operations. Skip the basics and dive into advanced techniques that will fine-tune and optimize your drawer slides for unparalleled efficiency and longevity.

Load Capacity

Adjusting the slide mechanism allows you to tailor the slides to different load capacities. Tightening the preload adjustment for heavier loads can provide added stability and prevent sagging. Conversely, loosening the tension settings can make lighter drawers operate more smoothly. This customization ensures durability and optimal performance across a range of industrial applications.

Material and Coating Choices

Choosing the suitable materials and coatings can significantly affect the life span and efficiency of your ball-bearing drawer slides. Materials like stainless steel and carbon fiber offer durability, while coatings such as Teflon or zinc protect against wear and tear.

These coatings also reduce friction, allowing smoother motion and less strain on the slide mechanism. It contributes to longer-lasting, more reliable drawer slides in demanding industrial settings.

Speed vs. Smoothness

These factors often come with trade-offs when it comes to ball-bearing drawers. A faster slide may require more smoothness for delicate operations, potentially leading to mishandling or breakage. On the other hand, prioritizing smoothness might mean sacrificing speed, affecting workflow efficiency.

To strike the right balance, consider adjustable damping features that allow you to control slide speed. Also, regular maintenance and the right choice of lubricants can help achieve quick and smooth drawer movements. This way, you get the best of both worlds without compromising performance.

Step-by-Step Guide: Quick Fixes

You’ve identified the issue and gathered your tools — now it’s time to roll up your sleeves and get to work. This section provides a step-by-step guide for quick and effective fixes for common problems with ball-bearing drawer slides. Whether it’s alignment issues or wear and tear, these actionable tips will quickly get your furniture back in tip-top shape.

1. Removing the Drawer

For safe and easy removal, empty it to eliminate any additional weight. Fully extend the drawer, and locate the release levers or tabs on the sides of the slides. These are often near the front, just behind the drawer face. Press or lift these components while gently pulling the drawer out. Doing so will disengage the drawer from the slide mechanism, allowing you to remove it safely without damaging any parts.

2. Inspection and Cleaning

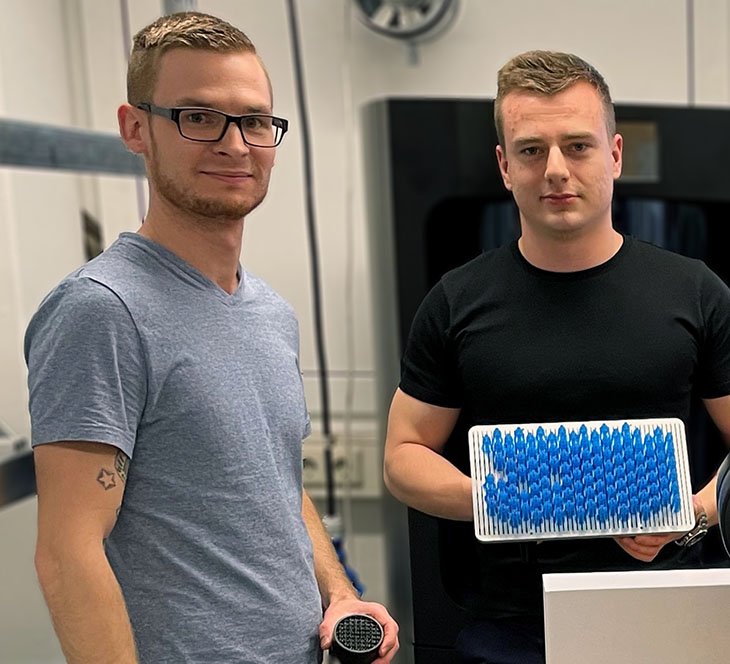

Examine the ball bearings, tracks and mounting screws for signs of wear, rust, or dirt. Any irregularities like pitting on the ball bearings or bent tracks indicate you need to adjust or replace them.

Use a soft cloth to remove loose debris and dirt for cleaning. Then, apply a mild detergent or specialized cleaner, using a soft-bristle brush to scrub away stubborn grime. Ensure to rinse off any soap residue and allow the parts to dry completely.

In addition, apply a thin layer of lubricant to the tracks and ball bearings. Opt for a non-staining, silicone-based product for metal-on-metal contact. Avoid grease, which can attract dust and debris, leading to future jamming issues.

3. Alignment and Adjustment

Loosen the mounting screws on the slides’ drawer and cabinet sides. Don’t remove them — just loosen enough to allow for slight movement.

Then, use your measuring tape or a laser level to check alignment. Make sure the slides are parallel to each other, and equidistant from the base or top of the cabinet. Once you’re confident in the alignment, tighten the screws back into place.

Consider fine-tuning with preload adjustments if your slides have this feature. It allows you to adapt the slides to different load capacities, achieving the perfect balance between stability and smooth operation.

4. Reassembly and Testing

Slide the drawer into the cabinet, aligning it with the tracks. Engage the release levers or tabs as you push the drawer in until it clicks into place. Tighten any screws you may have loosened during the adjustment process to secure the drawer firmly.

Consider sourcing all your materials from a single-source supplier to avoid issues with mismatched or incompatible components. Doing so ensures all parts work together, making repairs and initial installations more straightforward and effective.

Advanced Tips for Efficient Repairs

Preemptive maintenance is necessary to extend the life of your ball-bearing drawer slides. By regularly inspecting, cleaning and lubricating the components, you can catch potential concerns before they escalate.

Opt for high-grade materials like stainless steel or anodized aluminum, which offer durability and resist corrosion. Quality replacement parts may cost more upfront but will pay off in the long run through increased longevity and reduced maintenance needs.

Effectively Repairing Ball-Bearing Drawer Slides

Being proactive with regular maintenance is essential to lasting efficiency for your ball-bearing drawer slides. Don’t wait for problems to surface — instead, make it a habit to check on components regularly. This simple practice can catch minor issues before they become major headaches, keeping your operations running smoothly.