Waldmössingen, 03.07.2023 At this year's EMO, the world's leading trade show for metalworking (September 18-23, 2023 in Hanover, Germany), Schwäbische Werkzeugmaschinen GmbH (SW)will present two new products in hall 12 at booth C04: the two-spindle BA W03-22 CNC machining center and the BA profile, a new machine concept for machining profiles. Furthermore, SW will be showing the BA space3, currently its largest machine for machining battery housings, and will be offering insights into current trends in manufacturing such as friction stir welding and giga casting.

“Innovate Manufacturing” is the theme of this year's EMO, which also captures the very essence of SW's “Smart Manufacturing Solutions” corporate claim. “For us, innovative and smart manufacturing are two sides of the same coin,” says André Harter, Head of Marketing and Business Development at SW. “Both allow us to respond individually and efficiently to our customers' needs.” At EMO Hannover we also want to reinforce our 'Be smart. Be part' theme. This applies not only to sustainability, which we are driving forward at SW with our ECO2 machining programme. It also applies to our technology people. They are at the heart of our vision and our smart solutions.” At the world's largest trade show for metalworking, the market leader for multi-spindle machines will be exhibiting three machines from its extensive range of smart manufacturing solutions, two of them for the first time.

Efficiency boost for the automotive industry

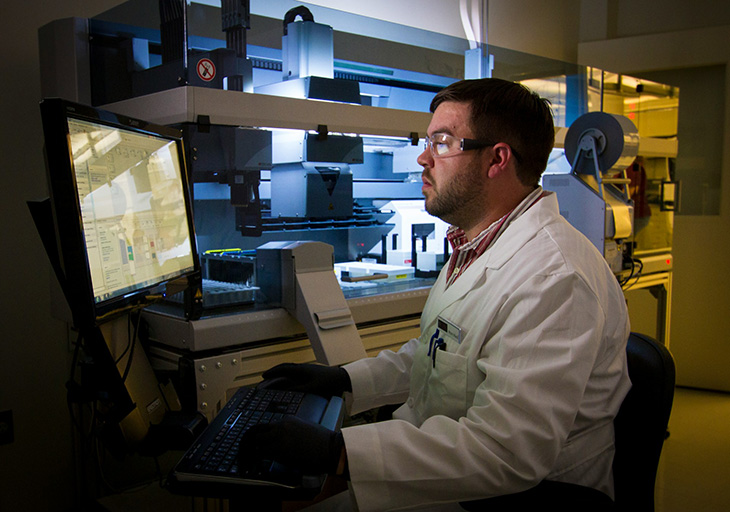

Productivity, flexibility, modularity, and connectivity: these are the most important factors for SW when it comes to meeting challenges with efficient system solutions in the fast-growing field of e-mobility. Case in point is the new BA W03-22 CNC machining center. Thanks to its high precision and efficiency, this two-spindle machine is ideal for producing high-quality workpieces in medium and large series for the automotive industry. Compared to a single- spindle machine, cycle times can be reduced many times over, ensuring maximum productivity. “We have expanded the proven machine concept of the model 3 series to include a two-spindle, double-station machine. It allows for faster axis accelerations with the linear motors installed in the machine,” explains Harter. “As a result, we achieve more power and speed compared to a ball screw as in the BA 322 model, for example with 20 percent faster chip-to-chip times.” With 300 mm of travel, The BA W03-22 also positions in G0 30% faster than the BA 322. . The machine is the first from SW to be equipped with Siemens Sinumerik One control.

Flexible machining with BA profile and BA space3

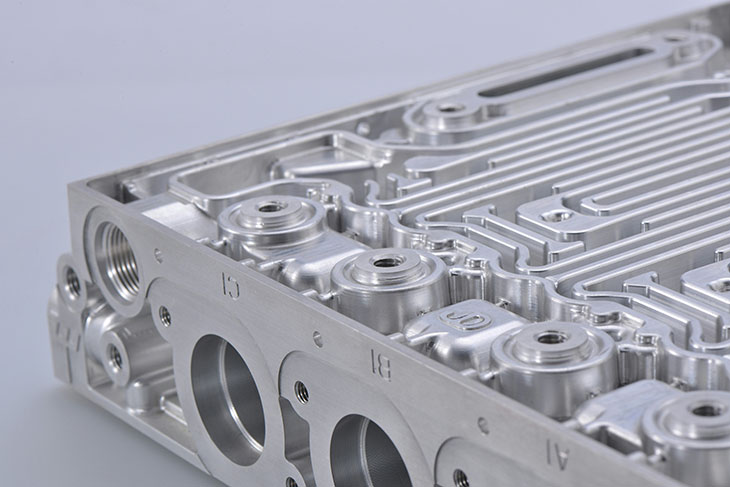

Another highlight in Hanover is the new BA profile. “It can easily mill profiles of various materials up to a length of 2,500 mm, for applications in the truck and automotive industries, amongst others,” explains Harter. Featuring a compact design, the two-spindle machine has two operating areas and allows machining on two worktables per side. It can be loaded either via automation or ergonomically by hand.

Also on display will be SW's BA space3, the largest machine in the company's portfolio to date. It is especially suited for machining large battery housings and numerous structural components needed for the growing e-vehicle market, as well as in the aerospace or agricultural industries. In so-called giga casting, instead of a multitude of individual parts welded or bolted together, only a few large components are used, each of which is cast and finished from a single piece. Underbodies, subframes, and entire front frames for the construction of electric vehicles can be created this way. At the booth, a robot will load and unload the BA space3.

Manufacturing trends at the booth in hall 12

SW will also present additional technologies for machining aluminum, steel, cast iron, cast steel and light metals at EMO. “At the trade show, we not only want to present our portfolio but also engage with customers, experts and professionals on industry topics such as sustainability, friction stir welding and giga casting,” says Harter, summing up his expectations for EMO 2023. “Thanks to friction stir welding, we are bringing more sustainability to manufacturing by working at lower temperatures and without shielding gas. This significantly reduces both energy consumption and emissions.”

More than meets the eye

”We want to surprise visitors at the trade show with the diversity of our system solutions,” concludes André Harter. “People often don't realize how wide-ranging our portfolio actually is and how extensive our expertise is.” With its flexible manufacturing modules, digital networking of the process chain, and intelligent automation solutions – developed jointly with customers – SW delivers customized manufacturing solutions that are precisely tailored to their individual needs.

Schwäbische Werkzeugmaschinen GmbH (SW) at EMO Hannover, hall 12, booth C04, September 18-23, 2023. For more information, visit: http://www.sw-machines.com/en