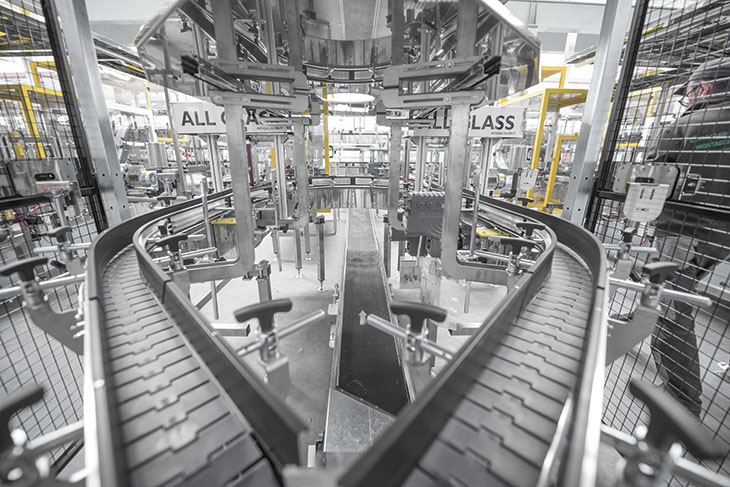

Schuler Servoline now available in different configurations and speeds, ranging from up to 12 all the way to up to 23 strokes per minute

Göppingen, January 25, 2016 – Efficient mass and series production on the one hand and smaller batch lots on the other: These are just two of the numerous challenges that automobile manufacturers all over the world have to face today. Possible solutions include the Schuler press lines. The so-called Servoline is now available in different configurations and speeds. The production rate – depending on the manufactured parts and the features of the line – ranges from up to 12 all the way to up to 23 strokes per minute. The fast lines are already established in the market, with the Servoline 12 and 14 now rounding off the range downwards.

The Schuler conceptions Servoline 12 and Servoline 14 are dedicated to customers who want to benefit from the basic features of ServoDirect technology and only need a medium production volume. Customers who plan to produce in high volumes or do so already might want to choose the Servoline 16 which offers more advanced technology and performance. At last, the Servoline 18 guarantees maximum volumes with the latest technology and best performance available in the market for XL-size equipment.

But this is not the end of the road yet: With up to 23 strokes per minute, the Servoline 23 – an L-size conception – is the world’s fastest press line. This is also because the line is more compact than the Servoline 18 and therefore allows a higher automation speed. However, despite the smaller press bed, nearly all of the typical parts produced on a press line can also be manufactured on the Servoline 23: skin panels, engine covers, floor parts, door parts and structural parts.

Automation makes the difference

Speed and production rate depend largely on automation. With the Servoline 23, 18 and 16, Schuler’s Crossbar Feeder is used for part transport. The reduced slide stroke in the Servoline 16 allows a maximum speed of 16 strokes per minute. The highest possible production rate of the Servoline 14 and 12 is defined by the robots in use for automation there. Nonetheless, Schuler’s Crossbar Robot 4.0 being used in the Servoline 14 has more speed than the standard robot in Servoline 12. Also, speed and movement curves are not defined here; the line is be optimized “on the fly” during production.

Yet, due to Schuler’s ServoDirect technology, each Servoline offers advantages in setup and maintenance, energy consumption and compatibility. Die change times as low as three minutes increase the production flexibility – in order to produce parts in smaller batch lots for a growing car model program.