Metso has received a repeat order for two complete tissue production lines for the Turkish Hayat Kimya A.S. Each production line will include an Advantage DCT 200 TS tissue machine, and they will be installed at the company's new mill sites near the city of Alabuga, Tatarstan, in Russia, and in the city of Mersin in southern Turkey. The start-up of the tissue machine to be installed in Russia is planned for the second half of 2014, and the second tissue machine will start up in Turkey at the end of 2015. The value of the order will not be disclosed.

The order follows the successful start-ups of two similar tissue lines supplied by Metso in 2010 and 2011.The tissue machine located at the mill in Yeniköy near the city of Izmit, Turkey, holds the world record in speed for tissue machines at 2,210 m/min.

"Metso has been a reliable and trustworthy partner for our previous installations and we are pleased to continue our good cooperation also in this new project," says Lütfi Aydin, Director, Paper Group, Hayat Kimya.

"We at Metso are very impressed with how Hayat has developed. Only seven years ago they were a newcomer in the tissue industry. Today Hayat is a global player in the tissue market and is also the current holder of the world speed record for tissue machines. The world class results show the strength of our partnership," says Jan Erikson,Vice President, Sales, Tissue Mills business unit, Metso.

The main part of the order is included in Metso's Pulp, Paper and Power first quarter 2013 orders received. The automation package is included in Automation's first quarter 2013 orders received.

Technical information

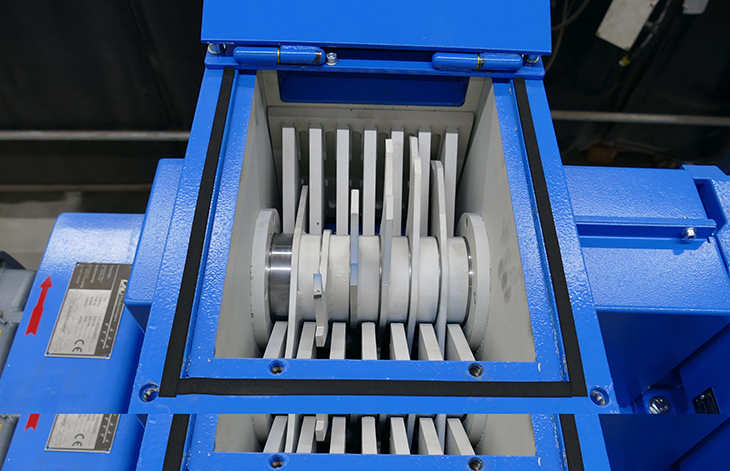

Metso's scope of delivery will comprise two complete tissue production lines featuring stock preparation systems and an Advantage DCT 200 TS tissue machine. Each machine will be equipped with an OptiFlo headbox, a Metso Yankee cylinder, an Advantage ViscoNip press, an Advantage AirCap hood prepared for co-generation, an Advantage WetDust dust system, an Advantage Run sheet transfer system and an Advantage SoftReel L reel. The stock preparation lines will consist of OptiSlush pulpers, OptiFiner conical refiners and OptiScreen machine screens.

Furthermore, the delivery will include an extensive automation package with Metso DNA machine and process controls and Metso IQ quality controls. Complete engineering, installation supervision, training, start-up and commissioning are also included in the delivery.

Both tissue machines will have a width of 5.6 m and a design speed of 2,200 m/min. The new lines will have a design capacity of 70,000 tonnes a year of high-quality facial, toilet and towel grades. The raw material for the new lines will be virgin fiber. The production lines are optimized to save energy and to enhance final product quality.

Hayat Kimya A.S. is part of the Hayat Group. The Hayat Group primarily operates in the chemicals, hygienic products, paper and wood-based industries. The Hayat tissue facilities today have a paper production capacity of 140,000 tonnes and a converting capacity of 100,000 tonnes per year. Through the new investment and ongoing projects the total production capacity of Hayat Kimya will reach 350,000 tonnes.