Metso has received an order from STX France to supply an advanced vessel-wide automation system, including sophisticated energy management solutions, to the world's largest cruise vessel, Oasis 3. Royal Caribbean International's third vessel in the Oasis class series is currently under construction at STX France's shipyard in Saint Nazaire, France.

Metso has a long track record of supplying automation technologies to Royal Caribbean International's cruise vessels over the years. Oasis 3 is scheduled to be handed over to the owner mid-2016. The vessel will have a length of 362.15 meters and a gross tonnage of 227,700. It will span 16 passenger decks, include 2,700 staterooms and accommodate 5,400 passengers in double occupancy.

"The world's largest cruise ship sets high requirements on the automation system, as it will control and monitor the electric power plant, air conditioning and swimming pools, among others, around the clock. The reliability and availability of Metso DNA's redundant vessel-wide system are of utmost importance," says John Weierud, Director, Marine Automation, Metso.

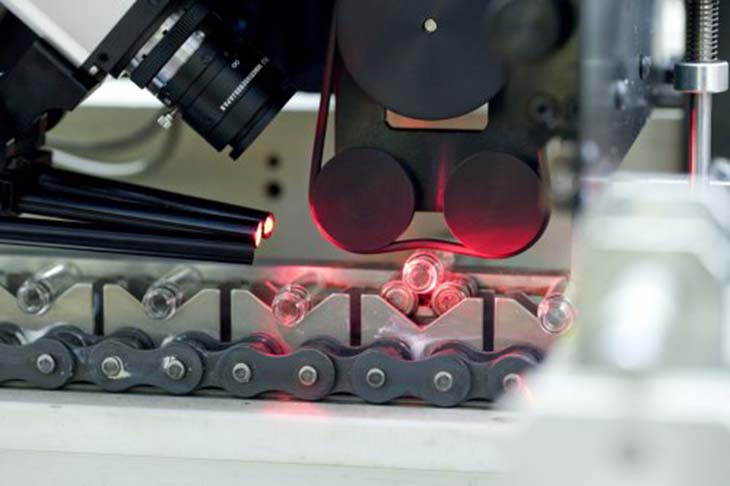

Metso's ship automation package encompasses machinery, air conditioning and emergency shutdown systems. The total system includes around 32,000 input and output signals, making it a considerably large system, not only for a ship but also compared with many land-based industrial automation systems. As the monitoring of energy flow and machinery performance is very important for a vessel of this size, Metso's Energy Management System will also be installed. Metso has long experience in energy management solutions for land-based industries, and this knowledge is now being made available for the marine industry, too.

In addition to the automation system platform, Metso's delivery scope includes engineering, programming, factory testing, technical assistance during quay and sea trials, and crew training. The dock trials are scheduled to start in mid-2015. The contract includes an option for a fourth Oasis-class ship. The order is included in Metso's Automation segment's fourth quarter 2013 orders received.

Ship automation since the early 80s

Ship automation systems based on Metso technology have a long history. Development work on ship automation systems started in the early 80s with Damatic Classic and has continued through to today's Metso DNA. The majority of installations have been for advanced ship types, such as cruise vessels. In particular, redundancy features and high product quality that guarantee undisturbed and safe ship operations have contributed to the success of Metso's automation systems.

The first automation system delivery based on Metso technology for a ship took place in 1983. To date, several hundreds of ships have been equipped with Metso's automation systems.

Metso has engineering resources with broad automation competence for machinery, power plant and air conditioning systems on board ships. Metso's marine automation solutions fit all types of ships and complexities, from crude oil carriers to passenger ferries, cruise ships, offshore supply and oil & gas processing vessels.

STX France SA is part of STX Europe AS, an international shipbuilding group. STX Europe comprises six shipyards in Finland, France and Norway in addition to nine shipyards belonging to STX OSV Holdings Limited. STX Europe Group has approximately 14,500 employees. www.stxeurope.com