For over 40 years FOS „Polmo” Łódź S.A. has been the biggest compressor producer in Poland. The company has been manufacturing automotive equipment and accessories since 1929 and its establishment goes back to the beginnings of the 20th century.

In the past, the enterprise would supply the whole automotive industry in Poland. At the current moment, its geographical scope of operations is much bigger. Thanks to the development of cooperation with foreign customers, most of Polmo Łódź production is exported. Written by Aleksandra Strojek

100+ years of tradition

The company was established in 1908 and no more than twenty years later, in 1929, it started the production of car accessories. After the World War II had been finished, the enterprise experienced some ownership changes. It was namely nationalized and transformed into a state-owned company. The next years witnessed extension of the product offer. The company took to manufacturing of carburetors for cars and motorcycles, developed motor S03 for the legendary Junak motorcycle and in 1956 released carburetors, fuel pumps and stationary motors of its own design. In the second half of 1960ies it also managed to receive Weber license for carburetors, Corona license for fuel pumps and Westinghouse license for compressors. In 1974 Polmo Łódź developed compressors, carburetors and pumps for FIAT.

Ownership and structural changes

The political and economic transition in Poland brought about many changes to the business activity of Polmo Łódź. In 1995 the enterprise changed its legal form again. After the privatization process, it stopped being a state property and became a privately owned joint stock company. As far as the legal issues are concerned, at the moment the main stockholders of Polmo Łódź are members of the management, employees and other natural persons. Right after ownership changes, the company decided to confirm the top quality of its products and in 1997 it introduced the ISO 9001 certificate. The year 2002 witnessed significant structural and organizational transformations. The enterprise separated its core activity – production of compressors – from the manufacturing of carburetors, fuel pumps and air compressor units. In 2003 ISO 9001:2000 was introduced and just one year later, in 2004, a new manufacture appeared on the product portfolio of Polmo Łódź. The company started the production of housings for turbochargers.

Cooperation with the giants

Thanks to the license received from Westinghouse as well as development of its own constructions, Polmo Łódź managed to acquire extensive know-how and competence in the area of compressors and their parts production. Until today, compressors with the enterprise’s logo are a synonym of a reliable, top quality product. The professionalism and knowledge of Polmo Łódź were the reason behind close cooperation with the most important market players of the automotive industry

– Knorr-Bremse, Haldex, Borg Warner Turbo System or Wabco. It shall be mentioned here that at the current moment Wabco (previously: Westinghouse) is the key customer of Polmo Łódź. The cooperation has been going on since 1968, when Polmo Łódź purchased license from Westinghouse. Next to Wabco, another giant of the trade and a direct competitor, which also located its orders at Polmo, is Knorr-Bremse.

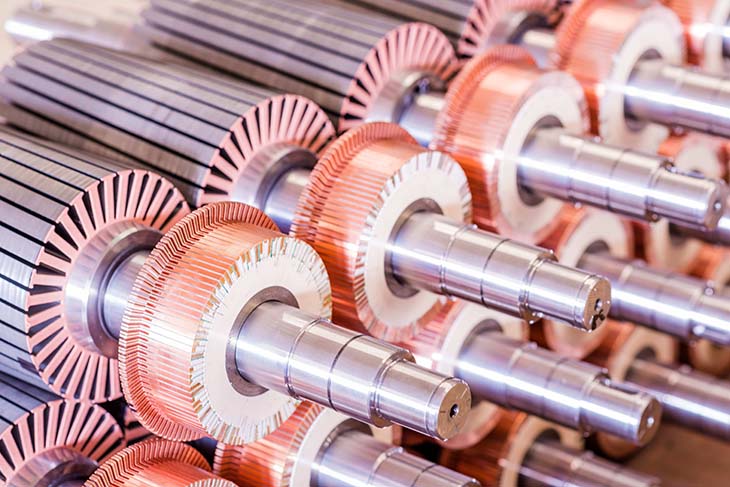

State-of-the-art machine park

Close cooperation with foreign partners, modern manufactures’ constructions as well as concentration on the quality cause that the company incessantly invests into its machine park. In this respect the enterprise has been taking advantage of the European Union funds. The co-financing of the investments started still before Poland’s accession to the organization. At the time, the subsidies came from the pre-accession programs PHARE. At the moment, Polmo is involved mainly in the Sectoral Operational Programs dedicated among others to small and medium sized companies. The funds have been used to purchase new machines as well as to equip the enterprise’s measurement laboratory. Owing to this ventures, Polmo can boast of a modern machine park which mainly consists of CNC machine tools. These machine tools assure repeatability and proper quality of the produced manufactures. The machine park was built in such a way that it meets the high requirements of foreign customers. The machine park of the company consists among others of the following CNC machines: vertical and horizontal machining centres, lathes, grinding machines, drilling, polishing and honing machines as well as many others. A supplement to the machine park are hardening furnaces and a furnace for plasma nitrification. Polmo Łódź is one of the very few companies in Poland which are equipped with the latter facility.

Product portfolio

At the current moment the product offer of Polmo Łódź includes:

- single cylinder or two cylinder piston compressors for pneumatic brake system, available in various types and varying with respect to cylinder diameters, total piston displacement, stroke, type of lubrication, cooling and working pressure characteristics, etc.,

- compressor parts (mass components production for compressor assembly as well as spare parts for aftermarket),

-designing and composing of the pneumatic brake systems for tractors,

- turbocharger housings,

- couplings for pneumatic brake systems.

Except for that, new machinery and modern measurement base let Polmo machine such parts as:

- crankshafts made of steel forgings and cast iron castings,

- cast iron and aluminum housings,

- valve plates cooled by air and water,

- cast iron cylinders – Plateau.

What is more, taking into consideration its compressor production know-how, Polmo started to design and complete the air brake systems applied in such tractors as: Farmtrac, Farmer and URSUS.

Awards in a number of areas

The high quality of the products, reliable and partnership based business contacts as well as dynamic growth of the financial figures resulted in a number of distinctions from various organizations and in diversified competitions. The distinguished areas of the enterprise’s business activity have been among others: exports, innovation, sales dynamics, relations with the employees and many others. The list of awards and prizes is then long and includes: the title of Gazela Biznesu 2005 (Business Gazelle), received from a prestigious Polish newspaper Puls Biznesu; nomination to the title of Solidny Pracodawca 2006 (Solid Employer) or the title of Supplier of the Year 2004. The latter came from a French company Knorr-Bremse.

Impressive sales figures

As mentioned before, for some time Polmo would supply almost the whole of the Polish automotive market. The structural as well as ownership changes, which took place at the beginning of 1990ies and concerned the majority of state-owned companies, resulted in their acquisition by foreign corporations. As the latter would start their own production, Polmo Łódź lost a significant share of its market. What helped the enterprise to overcome the hardships, was cooperation with foreign companies, for which Polmo Łódź manufactured compressor parts, first and foremost crankshafts and housings. Since the time, the cooperation has been deepened and extended by a number of new clients. Quickly developing market, a number of investments as well as relations with companies from the OEM market resulted in sales value of 15,8 mln euro in 2008. The scale of this figure is emphasized when one compares it with Polmo’s financial results from the year 2002. At the time, the enterprise’s sales leveled to 5,3 mln euro.

Turbulent market

Despite the fact that cooperation with the largest market players has had many positive effects for FOS Polmo Łódź, it has also influenced the company in the negative sense. It refers mainly to the recent financial crisis, which badly affected the automotive trade. The crisis reduced the production of the company by around 20-30%. In order to face the challenge, at the beginning of 2009 the company implemented a complex restructuring program. Its main goal was to adapt the company and its ventures to the new market situation and unfavourable economic indicators. An intensive cost-cutting and restructuring program allowed the company to overcome the worst six months. Next to that, new production process (aluminum parts) was introduced. The management of the company has also done a lot to start cooperation with new customers. In order to convince them to the producer from Łódź, the enterprise elaborated for them absolutely new compressors and their parts or modernized the old ones. The company is also proud that it managed to retain the best specialists and experienced professionals at its premises. It means that once the economy is back on the good track, Polmo Łódź will be able to quickly react to the growing demand coming from the customers.

What future holds

The strategy of FOS Polmo Łódź S.A. for the nearest future is first and foremost to strengthen the position of the company as the significant producer of the components for the automotive industry. This goal is to be achieved by further investments in new technology and modernisation of the machine park and equipment as well as extending the customer base and product diversification. The latter means introduction of new products applied in passenger car sector. The company is aware that the production level and sales figures will not quickly return to the values from the peak years. Yet, even the smallest upward trend in the business of the producer’s customers will allow Polmo Łódź to continue with the renewal of the machine park and carry out some investments in this area.