SpinDrive will use the funds to boost its global growth, helping industrial machinery manufacturers affordably achieve higher energy efficiency and productivity by providing a frictionless alternative to high-maintenance, oil-dependent, and energy-wasting bearing technologies. The company will also develop a new range of Active Magnetic Bearings for new applications.

LAPPEENRANTA, Finland (November 8th, 2023) SpinDrive, a Finnish company providing affordable active magnetic bearings for original equipment manufacturers (OEMs), has secured a €3.8M Series A funding round. The round was led by U.S.-based, hardware companies-focused investor Rhapsody Venture Partners, with existing investors Innovestor from Finland and Born2Grow from Germany also participating. The funding will enable SpinDrive to ramp up its commercial growth and improve industrial efficiency in factories worldwide.

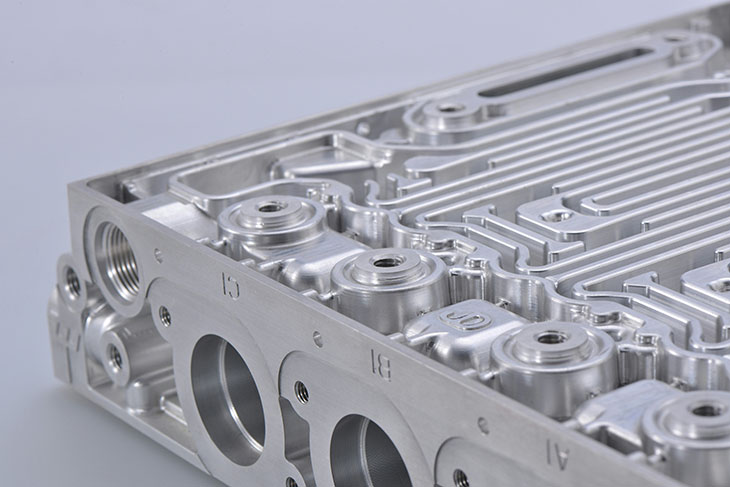

SpinDrive’s frictionless bearings are smaller, more energy efficient, and more affordable than its competitors. The bearings work through magnetic levitation, where there is no contact between rotating and stationary parts. No friction means no bearing maintenance for up to 20 years, even in high-speed applications, meaning high rotational speeds and energy efficiency without the risk of equipment downtime or maintenance breaks.

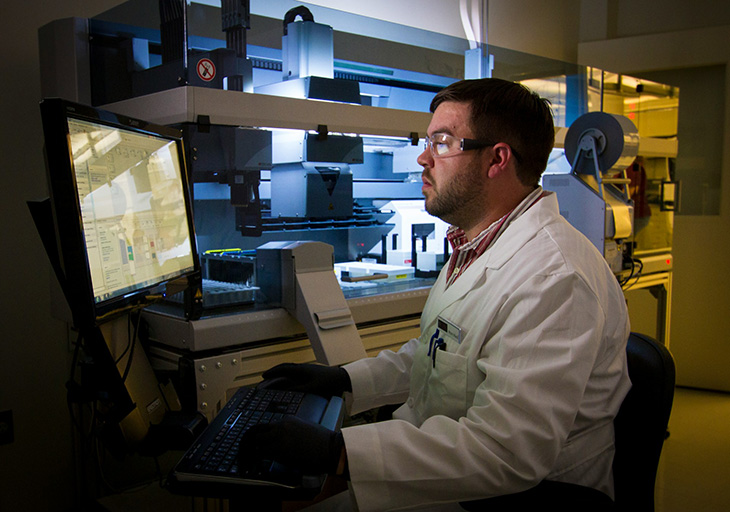

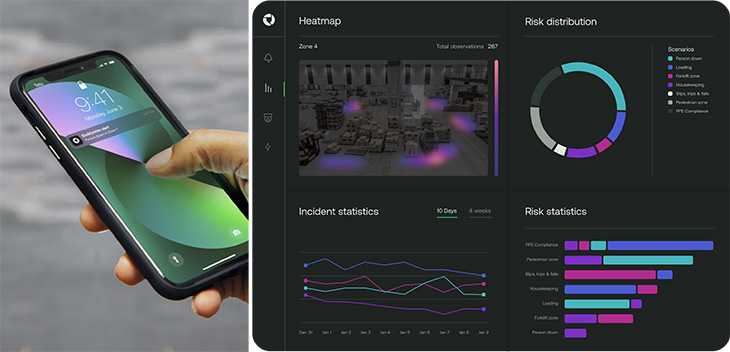

In striking contrast, traditional ball bearings in industrial high-speed applications have a 12-18 month maintenance cycle, requiring bearing replacement. SpinDrive’s bearings also provide condition monitoring and predictive maintenance of the whole machine, removing the need to install external sensors to monitor system health and reducing overall equipment maintenance costs by over 80%.

“We have seen increasing international demand for more energy efficiency and cleaner solutions in industrial production, and we are excited to build SpinDrive to meet those customer needs with our active magnetic bearing systems and controllers. With its specialization in industrial technologies and global reach into industrial companies, Rhapsody Venture Partners is an ideal partner for us, and we’re thrilled to be working with them,” says Nikita Uzhegov, COO and Co-founder of SpinDrive.

Furthermore, the bearings require no oil to work, eliminating the need for polluting lubricants from industrial production. EU factories consume 5 million tons of oil-based lubricants each year, and traditional bearing-based machinery suffers from high leakage and contamination risk. This lubricant-free operation makes production significantly more ecological. It also allows manufacturers to enter new markets, such as food, beverage, pharma, semiconductors, and hydrogen-based production, where hygienic, contamination-free

Another significant advantage is the energy-saving capability of frictionless bearings. For example, large machinery operating at 100kW to several MW requires considerable energy, and ball bearings limit machinery efficiency due to friction. Traditionally, OEMs’ use of AMB technology has been restricted by its size, cost, and complexity. By offering an affordable solution to overcome these limitations, SpinDrive’s AMBs and controllers enable manufacturers to reduce energy needs by as much as 15% by allowing increased rotational speeds in a vast array of systems beyond previously possible. This is a significant saving, as industrial electric motors currently stand for 46% of the world’s electricity consumption.

Improved energy efficiency is a key element in reducing industrial emissions. SpinDrive sees CO2 emission mitigation as one of its most significant contributions, and the company aims to help cut 500Mt of CO2 by 2050 annually by improving the energy efficiency of industrial machinery. New innovative technologies for fundamental machinery components, such as SpinDrive digital bearings, are essential in striving towards a carbon-negative future.

“Climate change is the biggest challenge of our time, but we often get stuck thinking about technologies like carbon capture when it comes to CO2 emissions. Industrial production is a massive part of the world’s energy consumption and climate emissions, so we must create energy-efficient and clean components to turn this tide. By improving the energy efficiency in existing and new machinery, we tackle the problem in a massive area and provide a significant impact,” adds Janne Heikkinen, CEO and Co-founder of SpinDrive.

The global bearing industry is currently worth €120bn. SpinDrive’s typical applications include turbo blowers, compressors, expanders, process machinery, flywheels, and energy recovery systems. High rotational speed yields high energy efficiency in transferring and compressing gases with turbo machinery, and frictionless operation cuts energy losses of spinning rotors.

“We scour the world for great hard science breakthroughs and love innovations that sell. SpinDrive’s system is much cheaper and better than anything else in the market. We are excited to partner with the team and to help grow SpinDrive internationally. ” says Carsten Boers, Managing Partner at lead investor Rhapsody Venture Partners.

The company has raised a total of €8M to date from a syndicate of VCs and private investors, as well as public funding. SpinDrive has the most advanced control systems for active magnetic bearings, with customers in Finland, Germany, the USA, Denmark, France, Italy, China, and the United Kingdom. The company has offices in Finland and Germany. SpinDrive has seen significant improvements in efficiency in its cooperation with current clients, such as global pulp and paper vacuum solutions provider Runtech Systems.

“Active magnetic bearing technology is a major leap towards more sustainable papermaking, with a very affordable total cost of ownership. 1 MW unit offers an unbeatable small footprint and material efficiency combined with low energy consumption over the product's lifetime. We look forward to deepening our cooperation with SpinDrive and continuing the application of Magma AMB controller in other machine models,” says Ville Lahdensuo, R&D Director at Runtech Systems.