The circular economy changes the production model by focusing on ways to reuse, repair, recycle or refurbish products rather than automatically producing new ones. Manufacturers can embrace this methodology by changing how they create their products and making them last as long as possible. Here are some methods forward-thinking companies employ and how they can benefit the environment.

Increasing the Use of Recycled Materials

Many producers follow circular economy best practices once new rules or regulations require doing things differently. For example, studies from the European Commission’s Joint Research Centre found that new automobiles account for about 10% of the plastic demand in the European Union. The commission used that data to justify a proposal mandating recycled content for cars and vans weighing less than 3.5 metric tons.

Some auto manufacturers are already investigating how they could use more recycled materials. That’s important because there’s still a lot of progress to make, even as such options become more common.

The plastic used for the seat belt covers in one of Audi’s vehicles comes from previously wrecked vehicles. At Ford, company representatives hope to use up to 700 pounds of recycled plastics per vehicle.

The recyclability potential spans beyond cars, too. Scottish camping gear manufacturer Vango developed a recycled fabric from single-use plastic bottles. That material is used for tents, backpacks, sleeping bags and chairs. Pet products company West Paw makes some of its toys from recycled ocean-bound plastic and materials from old toys that owners send back to the business.

Giving Consumers Sustainable Options

People who no longer need the products they’ve purchased tend to throw them out, and they end up in landfills. However, some companies engaging in the circular economy are changing that.

Ingka Group — the holding company overseeing most IKEA stores — launched the “Keep Good Things Going” campaign to urge customers to prolong the life spans of products bought from the Swedish furniture company. For example, IKEA locations have a buyback program where people can bring their previously purchased goods to be refurbished and sold to new customers. During a single year, 32.5 million products were sold that way.

IKEA product designers are more likely to make sustainable choices since the items they create may be used in multiple households. They may focus on using durable materials and eliminating weaknesses that could result in premature failures.

IKEA also provides spare parts for its products. Customers can order them to use furniture for longer, even if a critical piece gets lost. The spare parts program also requires IKEA’s designers to be thoughtful about product creation, potentially ensuring that specific extra components will work for multiple items.

Some of IKEA’s sustainable initiatives may even prevent consumers from entering its stores. A month-long campaign resulted in all the brand’s 20 Swedish stores arranging flea markets in its parking lots so attendees could sell furniture at low prices while giving the items new homes.

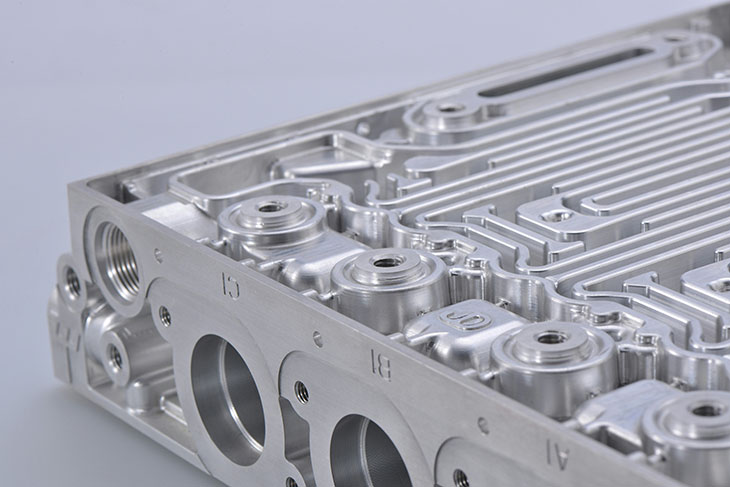

Reducing Material Consumption

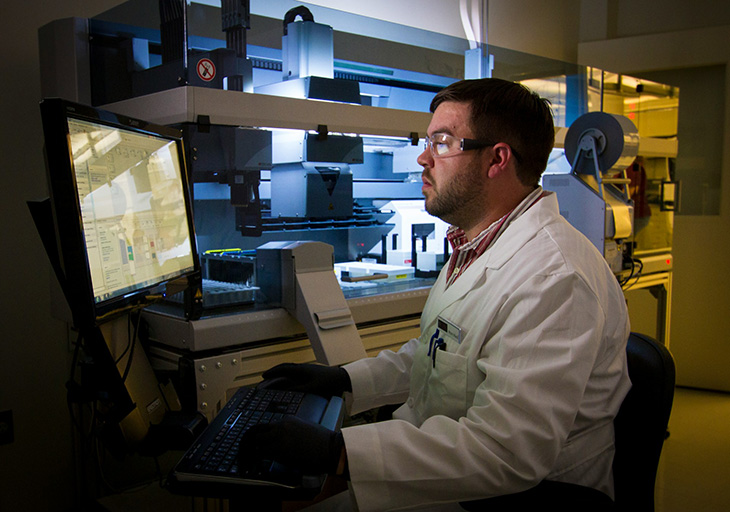

Manufacturers typically consume raw materials when producing new products. However, more efforts are being made to use once-discarded materials, thereby reducing the resources required.

Take cotton linter, the fuzzy fibers surrounding cotton seeds. People have traditionally treated it as a useless byproduct. However, linter is now used for Bemliese, a material that’s even softer than cotton after being soaked in water. It’s now converted to approximately 3% of the total yield.

Outdoor brand Patagonia does something similar by minimizing the need to use new fibers when producing some of its T-shirts. Consumers can return Patagonia T-shirts they no longer want or need, and the company uses that material to make a new fiber from post-consumer recycled cotton. The shirts contain recycled material and fabric from cotton industry waste.

These examples show manufacturers must take creative, thoughtful approaches when reducing material use. However, those efforts can pay off by supporting the circular economy.

Sustainable Manufacturing Requires a Willingness to Change

Consumers’ desire to engage in the circular economy is a relatively recent change, but manufacturers must be ready to accommodate it with more sustainable methods. They can start small, such as researching the market to learn about eco-friendly materials. Some companies may introduce single product lines and wait to see how those sell before scaling up. Others could form partnerships with entities that have extensive experience in furthering the circular economy, using that expertise to make informed decisions.

The circular economy requires a change in mindset, regardless of the specific methods manufacturers try. Instead of urging consumers to buy more and purchase often, the shift is toward prolonging life spans and repairing products instead of replacing them. It may seem like those changes will hurt the bottom line. However, strategic plans to tap into the circular economy can grow profits by catering to sustainably minded consumers who want to support companies that uphold their values.