Technological and social trends do not stop at component cleaning. It is not only new products, materials and production technologies that require adapted cleaning solutions. Topics such as energy and resource efficiency as well as advancing digitalisation are also changing the requirements in industrial parts and surface cleaning.

Component cleaning has established itself in all industrial sectors as an essential production step for downstream processes that meet requirements and for high product quality. However, the tasks have changed considerably in recent years due to structural changes in the industry. In addition, there are significantly higher requirements when it comes to the sustainability, energy and resource efficiency of cleaning processes. And last but not least, topics such as digitalisation and integration of cleaning in networked production environments as well as the use of AI are gaining in importance.

New applications due to the mobility and energy transitions

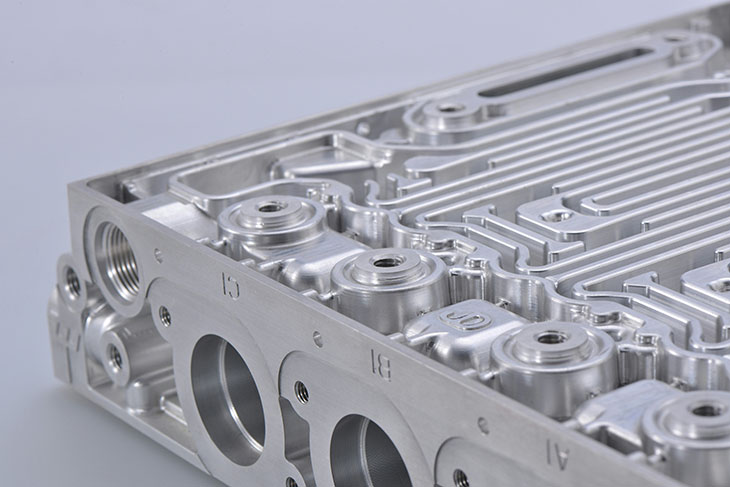

From electric vehicles and heat pumps to wind turbines and photovoltaic modules, products and solutions for the mobility and energy transitions are leading to new applications in industrial cleaning technology.

In electric mobility, in addition to the classic components such as those for steering and braking systems, there are also mechanical drive components which include stators, rotors, housings and gear units. In some cases, relatively high particulate and/or filmic cleanliness requirements have to be met for these tasks – which can usually be solved with wet chemical processes. Pre-assembled electromechanical components, on the other hand, require dry cleaning solutions. The requirement here is that they can be easily integrated into production lines – if necessary, subsequently – and enable efficient cleaning in the production cycle. The cleanliness of production equipment such as handling systems and grippers also plays a role here in order to avoid re- and cross-contamination. Cleaning in high-voltage technology, for example in inverters, is also receiving more attention. The focus here is no longer only on avoiding short circuits, but also flashovers. Various tasks for wet-chemical and dry cleaning also arise in the production of battery cells and systems, as well as fuel cells, in which the requirements for particulate cleanliness extend into the range of ten micrometres. Dry cleaning technologies such as laser cleaning are also benefiting from the trend towards the cold body-in-white in the automotive industry. In this context, bonding is increasingly used in car body construction, and the joining surfaces are selectively cleaned.

Sensor and microsystems technology on the rise

Irrespective of whether partially or fully autonomous driving or the advancing digitalisation of manufacturing processes is involved: reliable sensor, microsystem and monitoring technology is a basic prerequisite here, for example with camera systems. The demands on the performance and reliability of these virtuosos are becoming more and more demanding, and with ever smaller sizes. Indeed, the smaller the size, the more sensitive the reaction to impurities. Consequently, when cleaning the mechanical, electronic, optical, sensory or actuator components, extremely high demands on technical cleanliness must be met in some cases. This often requires solutions in the area of precision or high-purity cleaning, with production environments, such as a clean room, designed accordingly.

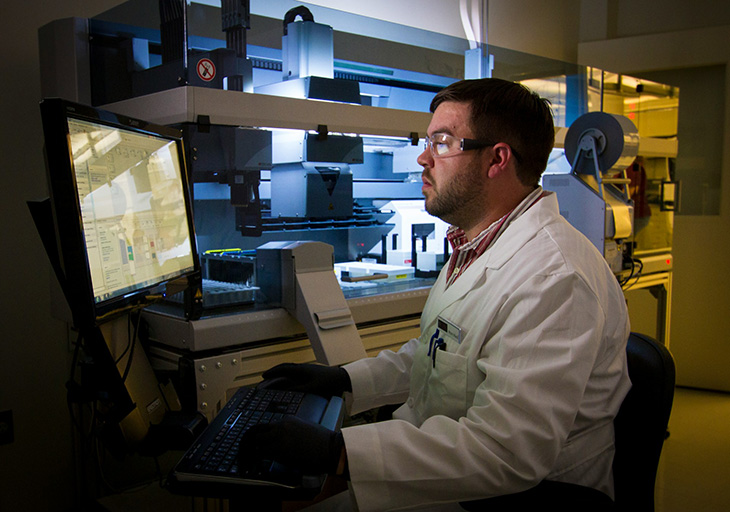

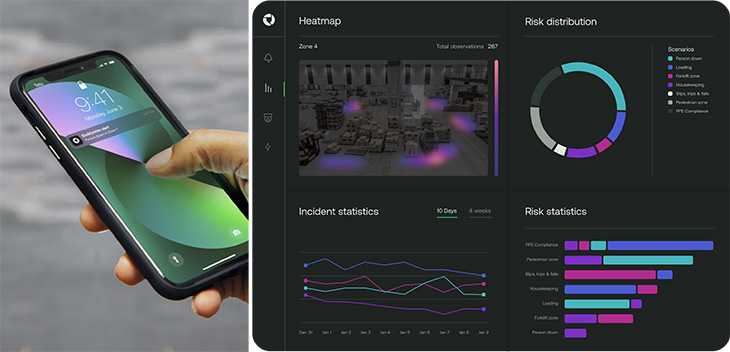

Automation and digitalisation of cleaning processes

The automation and digitalisation of cleaning applications has become an increasingly important topic. The requirements here go beyond the permanent recording, control and documentation of various system parameters, for example monitoring and readjustment of pressures and temperature as well as condition monitoring of aqueous cleaning and rinsing baths – which have already been implemented. In the meantime, there are demands for progress-dependent process control, meaningful monitoring of the process engineering sequences, and effective storage and provision of relevant process data and information on technical cleanliness. Solutions for implementing these factors are already being offered in some cases, and are being developed by practically all system manufacturers. One challenge is the availability and cost of metrological solutions. Likewise, manufacturers – often in cooperation with research institutes and/or partner companies – are dealing with the hot topic of artificial intelligence (AI).

Sustainability, energy and resource efficiency

Rising energy prices and stricter climate protection targets are increasingly turning energy and resource consumption into decision-making criteria for investments in a new cleaning system. Increasingly, this also involves the question of how cleaning affects the carbon footprint of the product in question. For existing systems, increased levels of interest are also apparent in solutions that make cleaning more sustainable and energy-efficient. To reduce consumption, manufacturers are offering, among other things, improved mechanical processes and more effective drying technologies, for example condensation drying with a heat pump. Heat exchangers, heat pumps and other systems for reducing energy demand as well as software solutions for optimised energy management are also on the menu. Solvent cleaning might experience a renaissance due to the significantly lower energy and resource consumption, provided it is just as suitable for the cleaning task to be solved as a water-based process. From this point of view, alternative cleaning processes that achieve technical cleanliness without energy-intensive heating of cleaning and rinsing baths as well as drying of parts are also becoming increasingly important.

Infobox parts2clean

parts2clean – leading international trade fair for industrial parts and surface cleaning

Which methods can be used to meet the cleanliness requirements of different components in reliable process and economically? What technologies are available for dry and partial component cleaning? How can cleaning processes be efficiently integrated into networked manufacturing environments? What factors influence the energy consumption of cleaning, and how can it be done in a more energy-efficient way? Answers to these and many other questions concerning industrial parts cleaning are provided by parts2clean. The leading international trade fair for industrial parts and surface cleaning will be held at the Stuttgart Exhibition Center in Germany from 26 – 28 September 2023. Comprehensive information will be available here about cleaning systems, alternative cleaning technologies, cleaning media, clean room technology, quality assurance and testing procedures, cleaning and transport containers, disposal and reprocessing of process media, handling and automation, service, consulting, research and technical literature. The three-day technical forum also provides a wealth of know-how on various component cleaning topics, with presentations featuring simultaneous interpreting. www.parts2clean.de/en.

Author: Doris Schulz