In various sectors ranging from manufacturing to shipping, the importance of precise and efficient industrial weighing cannot be overstated. The ability to measure weight accurately plays a crucial role in ensuring quality control, managing inventories, and optimizing logistical processes.

One company at the forefront of innovations in this area is the Gram Group, a leader in delivering cutting-edge solutions for industrial weighing.

The Digital Era of Weighing: A Revolution Led by Gram Group

The Advent of Digital Technology in Weighing

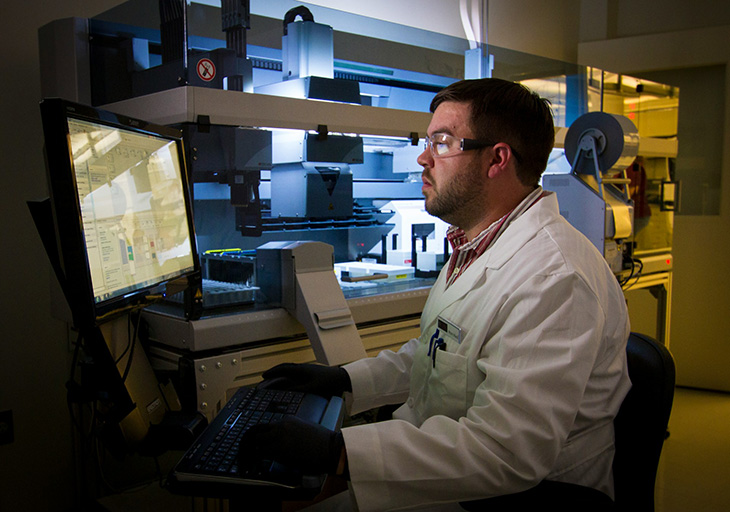

Digital technology has transformed many aspects of modern life, and industrial weighing is no exception. This digital transformation has led to more accurate, reliable, and flexible weighing systems. It is a significant shift from traditional analog weighing methods, which were often subject to human error and lacked the ability to easily store and transmit data. The advent of digital weighing technology has improved precision and efficiency, making it an essential addition in a variety of industrial weighing scales.

Gram Group: Pioneering the Digital Weighing Revolution

At the forefront of this revolution is Gram Group, a company that has distinguished itself as an innovator in the field of industrial weighing. With their Xtrem technology, Gram Group has introduced a unique and groundbreaking system that connects weighing terminals to any Xtrem platform. This pivotal innovation ushers in a new era of digital weighing, bringing unprecedented advantages to the industry.

Digital Convenience in Warehousing

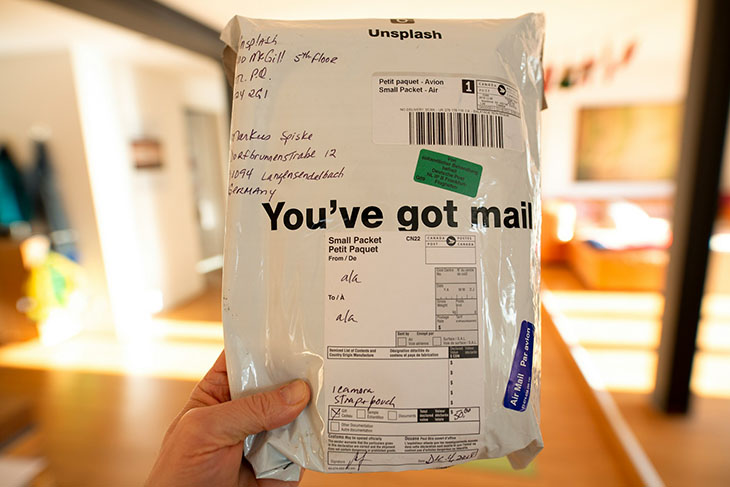

The digital era of weighing has brought significant convenience to warehousing operations. The Xtrem technology enables seamless and efficient inventory management by ensuring accurate weight measurements. It allows for real-time data collection, storage, and analysis, enabling warehouse managers to make informed decisions regarding inventory levels and distribution. Furthermore, the ability to integrate weighing data with other digital systems, such as warehouse management systems (WMS), enhances overall operational efficiency.

The Impact on Logistics

Digital weighing technology has also made a profound impact on logistics, a sector where precision and speed are critical. With Xtrem technology, logistics companies can ensure the accuracy of their cargo weights, which is crucial for cost calculation, safety, and regulatory compliance. The technology's connectivity features enable real-time tracking of weight data across the supply chain, ensuring timely and accurate information flow.

Transforming the Industrial Setting

Beyond warehousing and logistics, the digital era of weighing, led by technologies like Xtrem, is transforming the broader industrial setting. Industries that require precise measurement for quality control, such as manufacturing, can benefit enormously from this technology. The digital convenience of accurate weighing and data management ensures high-quality output, optimized production processes, and improved resource allocation.

The Future of Industrial Weighing with Xtrem Technology

The Xtrem technology from Gram Group represents the future of industrial weighing. Its advanced digital capabilities offer a range of benefits that extend beyond the weighing scale, impacting every aspect of industrial operations. As the digital era of weighing continues to evolve, businesses that adopt these technologies stand to gain a significant competitive advantage. With its ability to enhance precision, increase efficiency, and integrate with other systems, the Xtrem technology is truly a game-changer in the world of industrial weighing.

The Xtrem Technology: Empowering Industrial Scales with Autonomy and Flexibility

The Paradigm Shift: Xtrem Technology

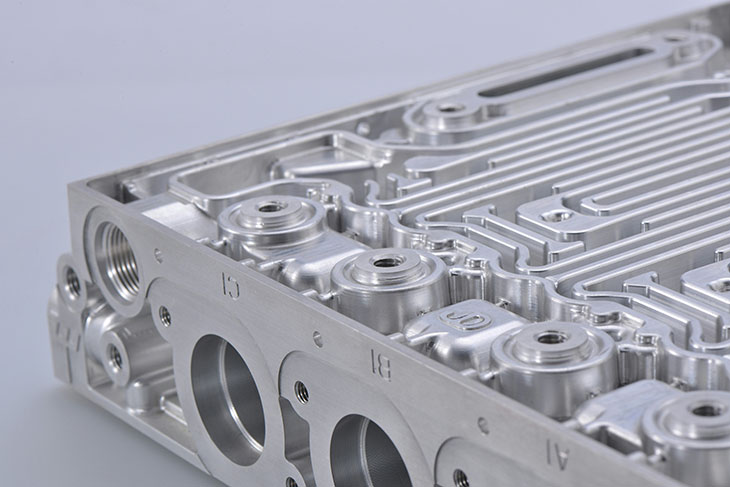

Gram Group's Xtrem technology represents a significant shift in industrial weighing by bringing autonomy to the scales. Contrary to traditional systems that rely on external devices for data storage and processing, Xtrem technology houses all weighing data within the platform itself. This innovative approach allows for streamlined and uninterrupted operations, thereby enhancing productivity and efficiency in industrial settings.

Complete Balance Autonomy: A Unique Feature of Xtrem Technology

One of the standout features of the Xtrem technology is complete balance autonomy. The weighing data is stored inside the platform, with terminals serving the purpose of merely displaying the information. This means that even if a terminal is unavailable or malfunctions, the data remains secure and accessible. This level of autonomy is unprecedented in the industry and offers a robust solution to businesses seeking to optimize their weighing operations.

Flexibility through Connectivity Options

The Xtrem technology further enhances its appeal by offering total flexibility in terms of data transmission. It can send data via both cable and WiFi, giving users the ability to choose the method that best suits their operational needs. This dual-mode connectivity ensures seamless data transfer and eliminates potential disruptions caused by connectivity issues.

Autonomy in Warehousing and Logistics

In the context of warehousing and logistics, the autonomy offered by Xtrem technology can significantly enhance operational efficiency. The ability to store all weighing data within the platform allows for real-time tracking and management of goods. This can help businesses streamline their supply chain, reduce inaccuracies, and improve decision-making.

Xtrem Technology's Impact on Industrial Settings

Across various industrial settings, the autonomy and flexibility provided by Xtrem technology can lead to substantial improvements in efficiency and productivity. Whether it's in manufacturing, where precise weight measurements are crucial for quality control, or in agriculture, where accurate weighing can impact yield estimates and resource allocation, Xtrem technology offers a reliable and efficient solution.

Looking Ahead: The Future of Autonomous Weighing with Xtrem Technology

As industries continue to embrace digital transformation, technologies like Xtrem that offer autonomy and flexibility will become increasingly important. By providing a reliable and efficient solution for industrial weighing, Xtrem technology is paving the way for a future where balance autonomy is the norm, not the exception. Its impact extends beyond the weighing scale, offering a comprehensive solution that can enhance various aspects of industrial operations. As such, Gram Group's Xtrem technology stands at the forefront of the future of industrial weighing.

Let's compare Xtrem technology with traditional weighing systems

|

Feature |

Xtrem Technology |

Traditional Weighing Systems |

|

Data Storage |

Internal, providing complete balance autonomy |

Dependent on external systems for data storage |

|

Connectivity Options |

Can send data via both cable and WiFi |

Primarily cable-dependent |

|

Flexibility |

Interchangeable indicators, multi-indicator and multi-platform compatibility |

Limited by physical connections and specific hardware compatibility |

|

Weighing Accuracy |

Very high resolution with Xtrem S high-resolution sensors |

Resolution limited by the technology used in the scale |

|

User Interface |

Data can be accessed and managed through multiple devices including PCs and Android devices |

Data access and management typically limited to specific terminal or PC |

|

Future Compatibility |

Equipped with WiFi and network capabilities for future technological advancements |

May require additional hardware or software updates for future advancements |

|

Convenience |

Quick indicator replacement without interruptions |

Replacements or repairs may cause operational downtime |

|

Integration with Other Systems |

Can be connected to any equipment on the network, facilitating integration with other systems |

May have limitations in integration with other systems due to proprietary connections and interfaces |

What Xtrem functionalities will help optimize weighing in your industry?

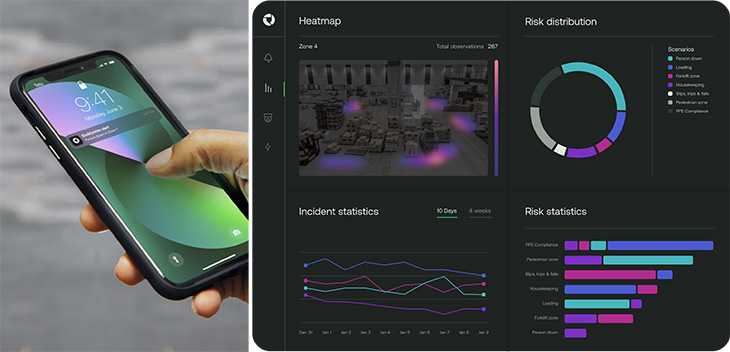

Multi-Equipment Compatibility:

- The Xtrem technology allows for a variety of equipment to be connected to the weighing system, including K3X, K3iX, MK3, and MK3P indicators.

- The system can connect through both a connection cable and via WiFi with the Xtrem PC application.

- With the WiFi option, it can also connect wirelessly to K3W, K3iW indicators, a PC with Xtrem PC software, and the Xtrem app on Android devices.

- Multi-Platform Compatibility:

- The Xtrem system allows for compatibility with any Xtrem platform, ensuring flexibility and adaptability across a range of operational setups.

- This feature is not limited to a specific device, enabling any compatible indicators and applications for PC and mobile terminals to obtain data from each Xtrem platform.

- High-Resolution Sensors:

- The Xtrem S high-resolution sensors offer superior accuracy in weighing, ensuring that your measurements are precise and reliable.

- This feature is particularly valuable in industries where precise measurements are critical, such as in pharmaceuticals, chemical manufacturing, and precision engineering.

- Configurable Autozero:

- This feature is useful for weighing tanks and silos, as it allows for automatic adjustment of the zero point, ensuring accurate measurements regardless of environmental conditions.

- Configurable autozero reduces the need for manual recalibration, saving time and ensuring consistent accuracy in measurements.

- Integration with Other Systems:

- Xtrem technology can be connected to any equipment on the network, enabling it to integrate seamlessly with other systems in your operational setup.

- This feature offers the flexibility to work with different equipment and systems, making it a versatile solution for various industrial settings.

- Digital Convenience:

- Xtrem technology provides digital convenience by enabling quick replacement of indicators without interruptions, thereby ensuring seamless operations.

- The system supports data transmission via cable or WiFi, providing flexible options for data access and management.