There are various ways to success. Some get right there in a short period of time, while others carefully take step by step reaching the goal.

JSC “Borisovskiy Zavod Medicinskikh Preparatov” was founded quite a while ago, and looking back at its history will help see the steps it took to reach its current position on the market. It is a modern Belarus-based dynamically developing pharmaceutical factory with new technology and high quality production. It is the biggest pharmaceutical enterprise in the Republic of Belarus.

The core business of enterprise includes production of injection preparations in ampoules and sterile powder antibiotic vials; tablet production; production of liquid phytochemical preparations and soft medical preparations; production of drugs in hard gelatinous capsules; production of original preparations based on oxidized cellulose.

Brief overview

The company was founded in Borisov, Belarus in 1965 and gradually became the leader on the healthcare products market of Belarus. Originally the company employed 250 people who were engaged in producing infusions, unctures, oils, and pills. But today the numbers are totally different from what they were. We are talking about 10 hectares of production area, over 300 technologies, and over 2300 skilled workers and specialists. The plant offers about 200 healthcare products names of 11 pharmacological groups on a regular basis. Yet, the number keeps growing to reach further heights. Borisovskiy Zavod Medicinskikh Preparatov produces healthcare products of all forms and kinds in demand nowadays. One of the major activity fields of the plant is the production of not less than 10 import substitution products (generics) per year. Working on the generics production is a labor- and time-consuming process that takes up to 2,5 years of work. But it has been proven by time and experience that these products are the most popular and demanded on the healthcare market - this makes perfect sense since the quality is the same as that of the imported products, but the prices are attractive for the consumers with different financial abilities. The unique combined products with hemostatic and vulnerary properties have a special place in the plant’s products portfolio. They include FERANTSEL tissues, OKSITSELANIM tissues, PROTSELAN tissues, LINKOTSEL uncture, PROTSELAN and others.

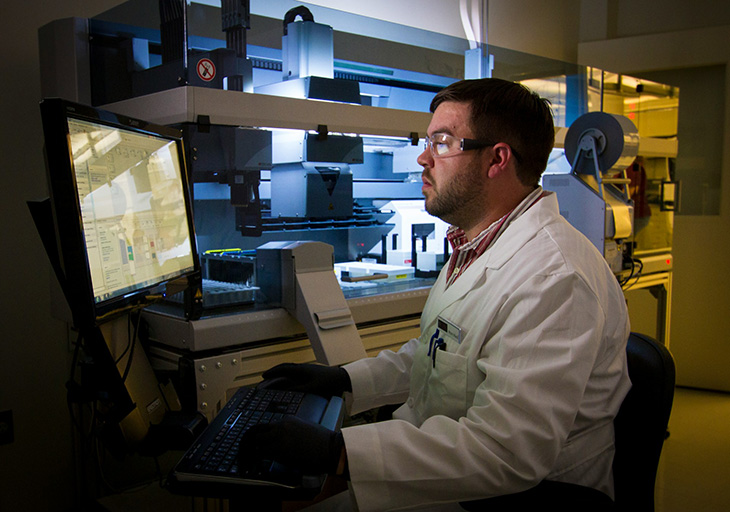

Improvement is an on-going process

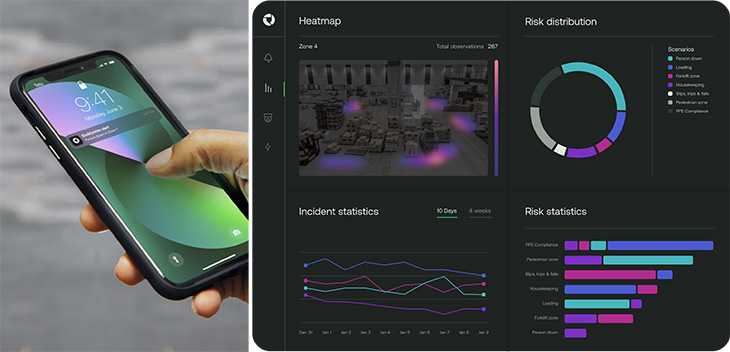

The production is being constantly improved with the usage of progressive technologies. Reconstruction and technical rehabilitation of all production areas are being carried out all the time. The plant has started a full-scale program of rehabilitation and modernization in the 80-s. A new pill section was put into operation in 1985. This section was expanded in 2000 to increase the production capacity by 40%. Today the section produces 210 mn packages per year. Ampoule production was put into operation in 1991, producing 360 mn ampoules. The production of injection antibiotics in extremely clean conditions was launched in 1995 producing 20 mn of bottles per year. And in 1997 the plant produced 1 mn of capsule medicines packages per year. 2003 was the year of reconstruction of the section for the production of unctures in tubes. 2008 and 2009 were the years of implementing a number of technical renovations: coating machine with perforated basket СМ-150 that allowed to increase the range and the volume of the production of pills with enteric coating; laboratory coating machine CM-10 allows to optimize the technological processes of pills covering as well as to produce small series of new products; vacuum station provided the section with vacuum impressively decreasing the power consumption (electricity, water); offset printer Heidelberger allowed to increase the range of printed materials for the main production; compression machine Sejong MRC-45 allowed to increase the range and the volume of the production of pills; sticky label applying machine allowed to improve the outward appearance of the bottles with infusions and to increase the competitive ability of the products; the NORDEN line of packing unctures into tubes and packaging tubes into boxes increases the range and the volume of the manufactured products; Dividela line of packaging the ampoules and bottles into a cardboard packing increases not only the range and the volume of the manufactured products, but also the competitive ability of the products on home and foreign markets. These are just few examples of the new equipment being implemented in the production process. Moreover, there is a quality unit working on the plant providing the control over the quality of the products according to the requirements of the corresponding GMP production practice and ISO standards. This unit consists of two departments. One of them is responsible for providing the quality of the products, and the other one is responsible for the quality control. Quality control department includes analytical and microbiological laboratories where specialists provide control over all stages of production. The laboratories are accredited as technically competitive according to the international standards as well as they are equipped with the newest analytical equipment of the leading world’s brands. The control is being carried out with the help of modern testing methods, such as spectral analysis, highly effective liquid and gas chromatography, finding bacterial endotoxins. Testing equipment is being constantly renewed. These aspects show that the plant administration is interested in offering the products of high quality in every way. The plant’s striving for the best results were also objectively noticed by the society. For example, Borisovskiy Zavod Medicinskikh Preparatov was a winner at the Best Exporter 2008 contest in oil-refining, chemical, and petrochemical industry category. Other countries opened their markets for Borisovskiy Zavod Medicinskikh Preparatov products, thus proving the high quality of produced medicines. Big amounts of the plant’s products are being shipped to all countries of the CIS (Commonwealth of Independent States) and Baltic countries and the United States of America. Going even further to other foreign markets is one of the plant’s major policies. The target markets are Western and Eastern European countries. The plant has serious chances to succeed in that task since over a third of the products are produced according to the GMP standards. Things like great reputation on the home market, modern technologies usage, and environment-friendly production contribute to the development of cooperation with foreign companies. The only in the CIS kidney machines and blood transfusion systems producing company was founded by Borisovskiy Zavod Medicinskikh Preparatov together with German concern Fresenius AG in 1992. Another useful cooperation for the plant is with the group of companies Aktavis. The cooperation resulted in the production and promotion on the home market of Fesam, which is a highly effective medicine that stimulates blood circulation in brains. New immune stimulating coneflower-based product ESTIPHAN was developed together with the research institute. And cooperation with Vitebsk State Medical University resulted in the production of bandaging products like KOMBIKSIN and DIOCEPT in the form of tissues saturated with medical substances of dioksidin and trypsin. The clinical tests proved that the bandaging products of the plant are highly effective and speed up the healing process by 2-3 times. The plants products is presented on different kinds of specialized republican and international exhibitions every year.

Numbers don’t lie

A little bit of statistics will help to see a bigger picture, which in its turn will help have a truer view of the company. For example, the volume of output in actual prices was 65 mn USD. 2010 is expected to have that figure raised to 73 mn USD. As to the export of the plant’s products, 35, 6 mn USD would be the number to describe the amount of the products exported in 2009. The company is in the process of starting the investment project with approximate total cost of 40 mn USD. The construction of the new tablet plant is expected to begin in years 2010-2013 starting the production in 2013 and reaching the project production capacity by 2014. Currently “Borisovskiy Zavod Medicinskikh Preparatov” JSC is looking for an interested investor to implement this project. Among the certificates of Borisovskiy Zavod Medicinskikh Preparatov the following can be mentioned: ecological certificate of the correspondence to the requirements of the standards STB ISO 14001-2005, the certificate of the correspondence of the safety, development, production and storage management to the requirements of STB 18001-2005 (OHSAS 18001:1999). Borisovskiy Zavod Medicinskikh Preparatov is an example of a confident walk to success reaching new goals, becoming better along the way and finding new peaks to reach.

Written by Kateryna Ferdyn