Sanden Manufacturing Poland is the leading air conditioning compressors manufacturer of the Sanden Group. Its motto, “delivering excellence”, has been both the goal and the guiding principle of the company on its road to success.

The following article is based on an interview with Junichi Tanabe (Chairman of the Board), Andrzej Michalski (Plant Manager) and Michał Romanowski (HR Director).

History and milestones

Sanden Manufacturing Poland company was established in 2004, one year later the production plant in the Polkowice subzone of the Legnica Special Economic Zone was opened. The company itself is a part of Sanden Holdings Corporation, a Japanese holding started by Kaihei Ushikubo in 1943, and currently the second largest manufacturer of car air conditioning compressors in the world. Sanden also has the largest global market share in vending machines in coolers. Ushikubo’s company exhibited remarkable capacity for adapting to the quickly changing world, offering a wide variety of products such as mica condensers, bicycle dynamo powered lamps and washing machines before establishing a partnership with the American Mitchell Corporation and embracing its current role as a manufacturer of compressors for air conditioning systems used in automotive industry. The company continued to grow and establish itself in more countries, and today parts it supplies are used in a quarter of all the cars produced worldwide. Sanden Manufacturing Poland was established to provide the Holding’s European customers with Sanden products, and has since become the foremost of the Holding’s sites. The production and storage areas have been greatly expanded in 2013. A second final assembly line was introduced, as well as multiple new process lines providing the base components for the final product. With its impressive output of three million units per year, the Polish branch is now responsible for over 50% of all air conditioning compressors manufactured by the Sanden group in Europe. Perhaps the most important event in Sanden Manufacturing Poland history was the opening in February of last year of Sanden Logistics Poland, the only such logistics centre of Sanden Holdings in Europe. The 6,500 square meters large warehouse with 6,200 pallet positions, situated next to the production facility in Polkowice and connected to it via transport tunnel, allowed the company to centralize the entire distribution and logistics process in a single location. The cost of the investment exceeded 13 million PLN and was developed in conjunction with Panattoni Europe, a subset of Panattoni Development Company, one of the world’s four largest industrial space developers. The general contractor for the logistics centre was Mirbud S.A, a company with thirty years of experience in construction and more than 350 prestigious projects in its resume.

Production

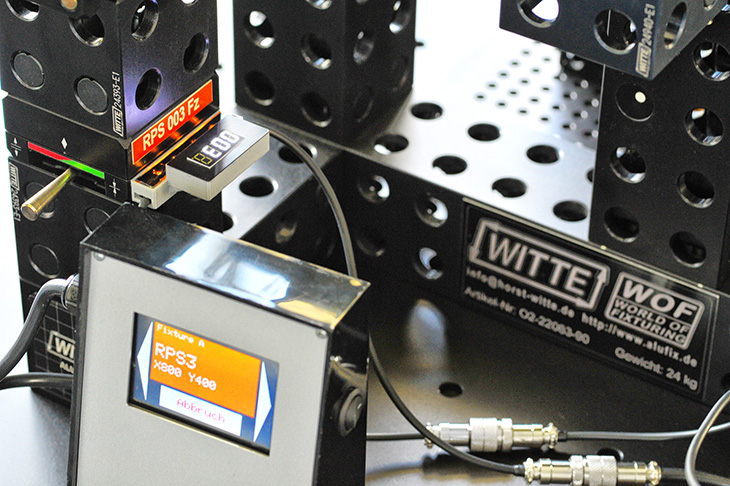

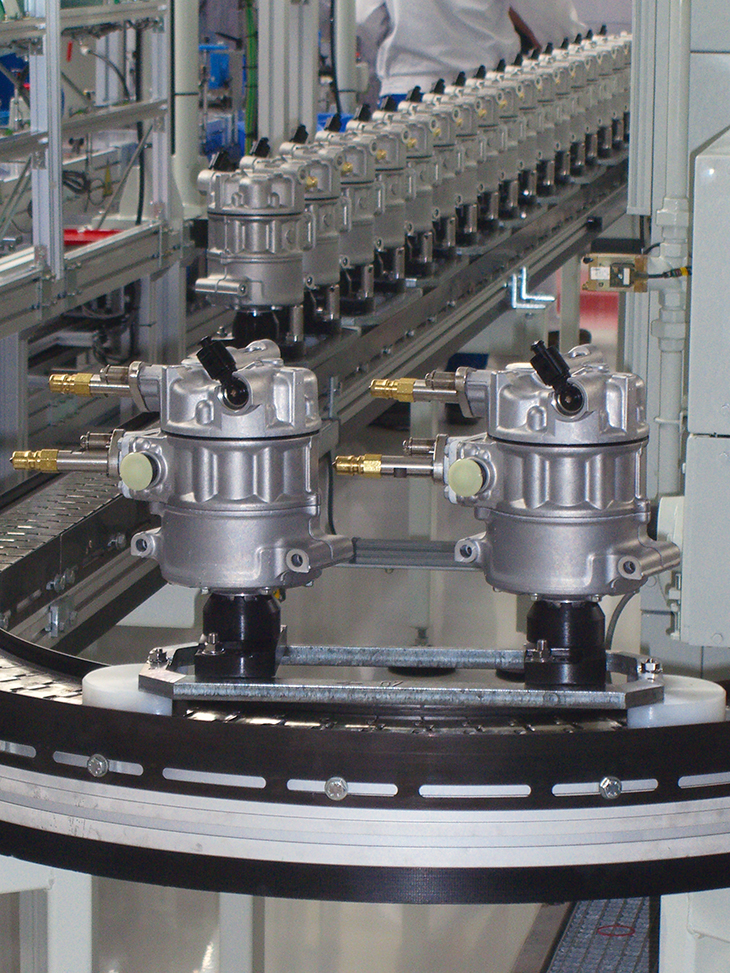

The main production focus of Sanden Manufacturing Poland are PX series air conditioning compressors. There are currently two final assembly lines and twenty six process lines for tasks such as electron beam welding, coating, sanding and precise machining. Machines that make up the production lines have been supplied by the best manufacturers in the industry, such as MTI, Micron, Muratec, Makino and Brother. Industry’s standard technologies have been improved by including innovations such as friction welding of aluminum elements and casting moulds micro-spraying. All of Sanden’s products undergo rigorous quality control. The production process is controlled and every step is designed to ensure the compressors are up to strict specifications of cleanliness, noise levels and infallibility. Other than the compressors, the production plant in Polkowice also produces HVAC (heating, ventilation, and air conditioning) modules responsible for air distribution and temperature control in vehicle cabins. There are presently two HVAC assembly lines, with overall production capacity of 150 thousand units per year. Currently Sanden provides HVAC modules for five models of Scania (a major Swedish manufacturer of commercial vehicles) trucks and two DAF (Dutch truck manufacturing company, a division of Paccar) models. Sanden Manufacturing Poland’s other important partners include the biggest companies of the automotive industry, such as Aston Martin, Land Rover, Volkswagen, McClaren, Ford, Jaguar, GM and Opel. It is however important to note, that Sanden has numerous clients and itself relies on multiple suppliers, and all of those partners are treasured equally by the company. In accordance with its “delivering excellence” motto its goal is to always achieve the highest possible standards and deliver perfect quality, a task it can only be equal to thanks to flawless cooperation with all of those partners. Sanden’s operations are conducted with minimizing any negative impact on the environment. Sanden is an eco friendly company, engaged in multiple projects benefitting the natural environment. In Japan, the company has been recognized by the Organization for Economic Co-operation and Development and received an award for Sustainable Manufacturing Good Practices.

Human resources

Neither the success of Sanden Manufacturing Poland nor its parent company would be possible without the hard work and experience of its employees. Since 2011 has doubled its workforce, and currently employs 1184 people. Recognizing their importance, the company continuously invests in its employees, providing them with on the job training (the method SMP puts the biggest emphasis on) and other kinds of internal and external training, as well as opportunities to participate in conferences and work on various projects. Teamwork is the key for SMP, and the company relies heavily on Small Group Activity ( SGA) problem solving method, wherein small teams of five to seven people, drawn from related departments, work together to present solutions to particular issues. The groups utilize the so called QC Story or quality storyboard method for illustrating the quality control process and PDCA (Plan-Do-Check-Action) based improvement methodology. The SGA approach to problem solving helps new employees to integrate quickly and easily, and helps them to showcase their unique talents. Sanden Manufacturing Poland is one of the leading companies in the world developing this problem solving approach. Another important feature of SMP’s approach to allowing the employees to help improve the company is the “leader index”, an anonymous poll conducted every six months wherein the employees evaluate their leaders/managers leadership and communications skills and their ability to motivate subordinates. The analysis of the poll results followed up by necessary improvements aimed at raising employee job satisfaction are key to ensuring the work environment remains friendly, open and conducive to highly efficient work and innovation. Equally important is the company’s corporate social responsibility policy. Sanden Manufacturing Poland is dedicated to supporting equality, by supporting women and handicapped employees. Pregnant employees can expect flexible work hours as well as an adjustment program to help with returning to work after maternity leave. SMP also supports charity, local vocational education (through tours for students and internship programs) and employee sports teams (soccer, volleyball).

Looking into the future

Following rapid growth in recent years, the primary task of the company in near future is stabilization and optimization and fine-tuning of all those innovations and investments to maximize effectiveness. Nevertheless, while there are currently no plans for further expansion of Sanden’s facilities in Polkowice, the ever evolving nature of the market necessitates anticipating future changes. One of such changes is the increasing importance of electric cars for the automotive industry, and SMP is considering making producing components for such vehicles its next step.