Established in 1991, CMT is one of the leading manufacturers of tilt semitrailers, dump truck semitrailers, trailers, bodies for truck chassis, as well as specialised equipment, tilts and advertising materials.

Thanks to the company’s determination, passion and willingness to adjust to customers’ needs, its products enjoy great popularity not only in Poland, but also on other European markets.

Written by Anna Chudzik

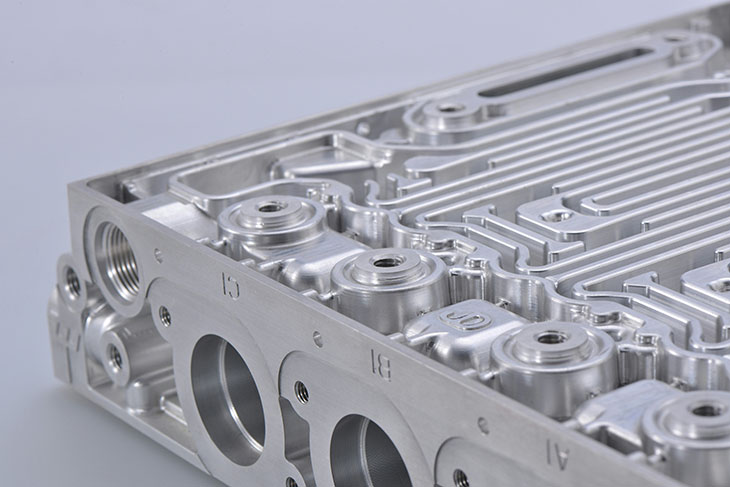

Modest beginnings

The company was established in October 1991 in the form of a partnership and named “Chojnickie Maszyny Transportowe” Faryna, Klunder, Mięsikowski, employing only three staff members apart from the three owners. At the beginning, the company’s profile revolved around the production of machinery for the food industry, but soon after, CMT started manufacturing goods for the transportation. In November 1994 the owners bought both the land and the buildings in Chojnice, but when production exceeded the capacity of the plant, the company decided to additionally lease out premises in Brusy. The wide recognition of products, which were systematically growing in number on the domestic market, triggered off the decision to start production earmarked for export. That moment can be considered a milestone in the history of the company, and as a further boost for development. The thriving business also resulted in the steady growth in the number of employees. What particularly came in useful for construction engineers was the implementation of the ProEngineer program, which is one of the world best integrated 3D solutions, used by manufacturers for mechanical engineering, design and manufacturing. Moreover, the company systematically enlarged its machine facilities, e.g. by putting a paint chamber or a numerically controlled plasma cutter into operation. In 2002 the company made a contribution in kind to “CMT” Chojnice Sp. z o.o. (limited liability company). Two years later a new production hall was opened, where the final assembly takes place. Yet another important year was 2005, when CMT received the ISO 9001:2000 certificate, which objectively asserts the high quality of services delivered by the company. As one can see, the company has been a major success story. Once a small enterprise with a handful of employees, CMT currently employs 130 people and has share capital of PLN 4,023,000. More than 18 years of experience resulted in top quality products and the capacity to handle even the most demanding tasks.

Trailers, semitrailers, dump trucks and more…

Over all years of activity CMT widened the range of its products successively. Nowadays the company can boast a wide array of products on offer, ranging from various kinds of semitrailers and trailers through different truck bodies, to carriers and lifts. CMT semitrailers are available in the following forms: tilt semitrailers, box semitrailers, platform semiltrailers, semitrailers with movable floors and container semitrailers. One can also find self-dumping trailers and semitralers with a rear or side dump, and various sorts of truckbodies for truck chasses of different brands. The bodies can be offered in the tilted, box, container, and self-dumping versions (three-way or rear dumping). Self-dumping vehicles are equipped with aluminium or steel boxes of rectangular section or chute section, which are designed mainly for transportation of aggregate, gravel, or bituminous bulk. The products which have recently enjoyed the greatest popularity in the category of semitrailers are dump truck semitrailers as well as low chassis CMT NSP-24 models, which are strengthened and adapted for the transport of construction machinery, such as loaders, road rollers, crushing machines, forklift trucks.

Quality control

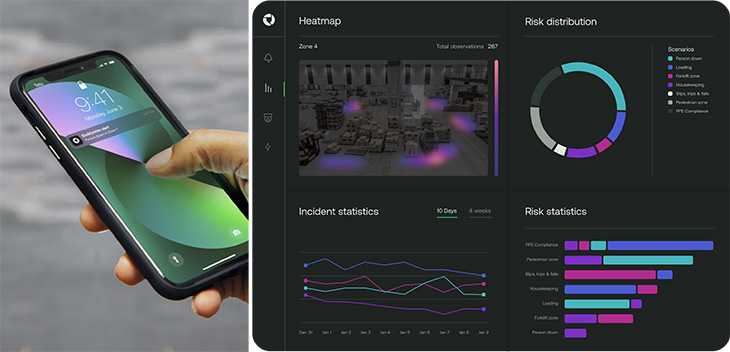

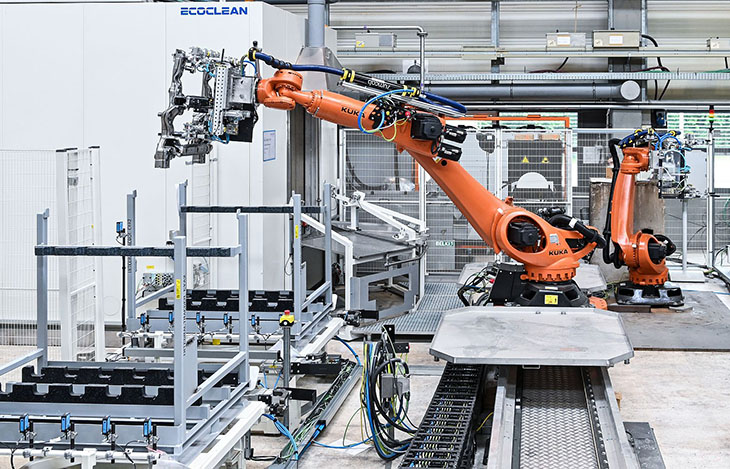

From the initial stages, CMT has strived to ensure high quality of its products, especially in terms of the aesthetic appearance, exploitation parameters and durability. ISO 9001:2000 certificate asserts that the company applies a Quality Management System for designing, production, service and sale of transport devices. 3D model of products are created by the team of specialized personnel in the Construction Technology section. It allows the company to eliminate any construction flaws and potential interference of the elements. Moreover, CMT carries out the durability tests, using the finite element method (FEM), which also helps to improve the process and reduce vehicle curb weight. All products are manufactured in a modern factory floor and then they undergo the shot blasting process. After that they end up in a paint shop, where they are coated in protective layers. The company puts emphasis on the control of its products, which is why, after the final assembly of components and installations, each product undergoes the technical acceptance in the Quality Control section. It serves as a guarantee for a faultless product that will correspond to the order. As for the components used in the CMT products, they belong to the top-notch companies in the world.

Each product is a novelty!

Since the company presents a customer-oriented approach, its objective is, within its capacity, to live up to all expectations and satisfy its customers by delivering the products they wish. All CMT products are customized to the individual needs of clients. The company accepts individual orders, which makes each and every vehicle one of its kind. The flexibility of the company, as well as the ability to accept all orders, can be exemplified by the dump truck semitrailer with a steel box, which is earmarked for the Swedish market and designed to transport bituminous bulk. The box is insulated in order to minimise the loss of heat while transporting hot bulk. Thanks to the possibility of changing the pressure on the movable truck of the semitrailer, obtained by changing the distance between the pin and the axles, it perfectly fits into the Swedish needs and regulations of the law. The hydraulic system is used in the movable truck, as well as to open the back of the truck, and also to open and close the roof, which is made of the canvas cover stretched over the steel frame. The company also strives to anticipate the clients’ needs, so it is open to any suggestions and remarks concerning the exploitation, which would help to improve the product quality. It is also worth mentioning that CMT has been widely appreciated abroad. Its products find application not only on the domestic market, but they also reach Denmark, Sweden or Norway.