Leading manufacturer of hand tools to produce on Bêché KGH 2.5B system with a working capacity of 25 kJ

Göppingen/Steinbach-Hallenberg, August 31, 2021 – Since its founding 60 years ago, SWM Werkzeugfabrik has earned a reputation as an excellent drop forge, supplying high-quality pliers and torque wrenches to the industry, automotive workshops, and aviation, among others. The company processes up to 25,000 blanks a day at its production site in Steinbach-Hallenberg, Thuringia. In the future, a down stroking hammer from Schuler will also be used for this purpose.

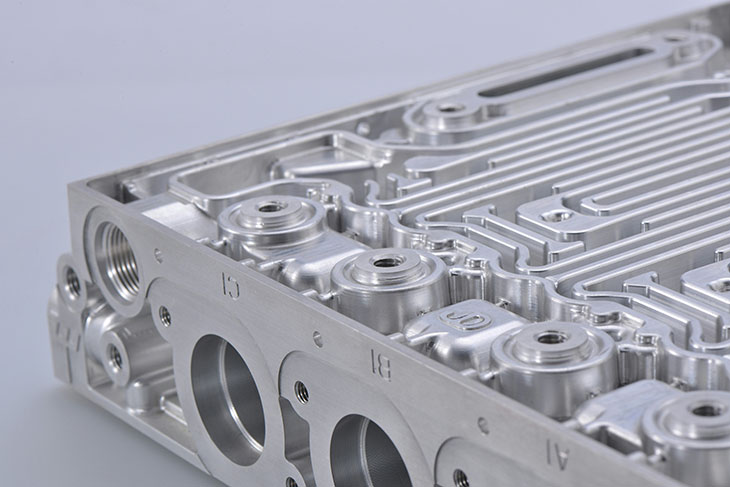

The 36-ton Bêché KGH 2.5B system with a working capacity of 25 kilojoules replaces a competitor's hammer and can use the existing foundation for this purpose. The solid, one-piece U-frame design, in conjunction with precise, large-area guides and a new generation of proportional valves, enables high forging accuracy. The hydraulic down stroke drive ensures high blow sequence numbers with minimum pressure contact times. Impact energy and impact sequence can be precisely adjusted via the control system.

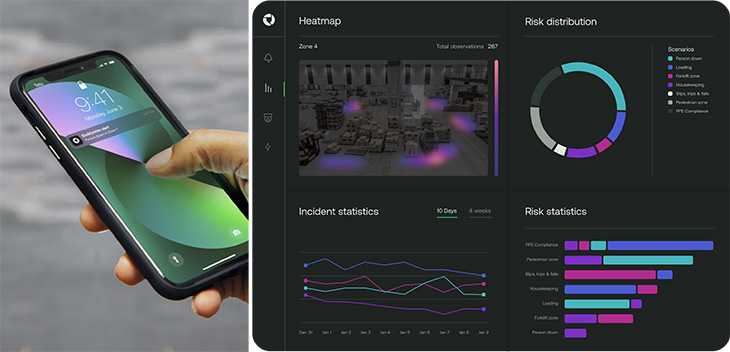

"The fact that SWM has chosen Schuler for the first time speaks for our technological leadership also in hot forging," emphasizes Managing Director Frank Klingemann. SWM operations manager Sven Kettner adds, "The decisive factor for us was that the hammer already has all the prerequisites for remote monitoring of the operating status." Schuler has gathered the corresponding solutions for monitoring production, cooling and lubrication circuits, and drives in its "Digital Suite".

The customer manufactures the required dies in just two weeks in its own die shop. The material being forged is heated by gas, electrically or inductively. SWM has been part of the Stahlwille Group since 1996.