For a couple of years now, robotic automation has been steadily on the rise. According to a recent study by Statista, the global spending on industrial robots is set to exceed $24 billion (€21 billion) come 2025. As the world continues to battle the on-going pandemic and all the challenges that it brings, robotic automation is taking on a new and extremely important role. As highlighted in an article by Euro News, in countries like Russia, China and Singapore, robots are being utilised to limit friction points and ensure that everyone is observing the universal social distancing protocols. Aside from being deployed for essential cleaning, shelf stocking and deliveries, robots are also being stationed in parks to encourage everyone to stay six feet away from each other.

Post-pandemic or not, the world is having to quickly adapt to AI. Although the pandemic did not to introduce new technologies, it did hasten the adoption of the current ones - and that is exactly what happened with robotics. Following the dramatic slump in investment and the significant rise in unemployment, firms are looking at robots as the very technology that will help them shore up their balance sheets. One company that is doing this is the German multinational company BMW. Recently, BMW announced that it will be using Nvidia’s Isaac robotics platform to add advanced computing and visualisation to its factory logistics robots. Another company that is turning to robotic automation is the UK’s largest sandwich maker Greencore. Patrick Coveney, the chief executive of the company, said that their decision to speed up their automation strategies was inspired by their goal to strictly adhere to social distancing rules and increase productivity, as well as efficiency.

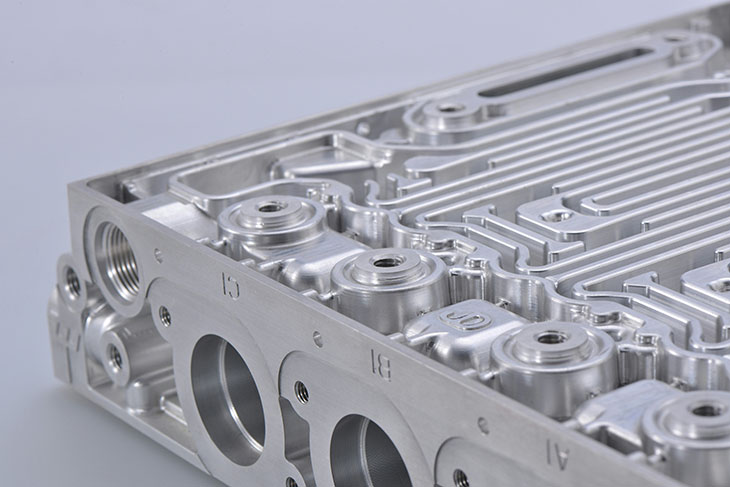

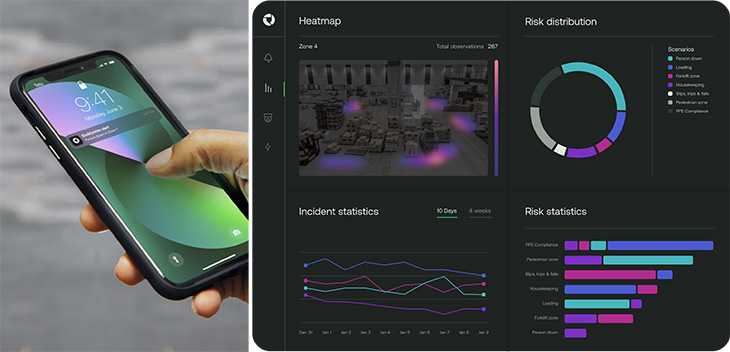

Aside from empowering businesses, robotics automation is also instrumental in making sure that companies belonging to any industry strictly observe and adjust to the world’s new normal. For instance, Elementary Robotics “full-stack” robotic solution aims to assist various enterprises in preparing for the onslaught of operational changes they will likely face, thanks to the on-going global health crisis. In order to do this, Elementary Robotics equipped their robots with motor controls and API that promote sophisticated machine learning. And with robotics having the latest in power delivery system design integrated into their components, they can easily create output signals for RGB cameras and depth sensors that enable AI to interact with the world. This shows how technology is already at a stage where robotic-to-human interaction can easily become the norm.

Unfortunately, while robots have proven themselves to be very effective in limiting human-to-human interactions and boosting businesses in a post-pandemic world, they are also threatening the livelihood of many - especially those who are in developing countries. For instance, in the field of manufacturing and logistics each new industrial robot wipes out 1.6 manufacturing jobs. On a global scale, that translates to about 20 million jobs in the same field that could be replaced by robots by 2030. Experts and economists predict that the integration of robotics automation into various industries will translate to a boost in employment and economic growth, thereby creating as many jobs as they displace. However, this is still a prediction and low-skilled workers will still be more vulnerable than white-collar workers in the face of automation. Something the pandemic has already made very clear with the difference in unemployment levels.

It is therefore up to the world’s many governments to ensure that the pandemic hasn’t sped up automation at the expense of jobs. What is clear though is that this crisis has shown how ready the world is for robotic automation.