Preliminary trade fair report for Blechexpo 2019 (05 to 08 November in Stuttgart)

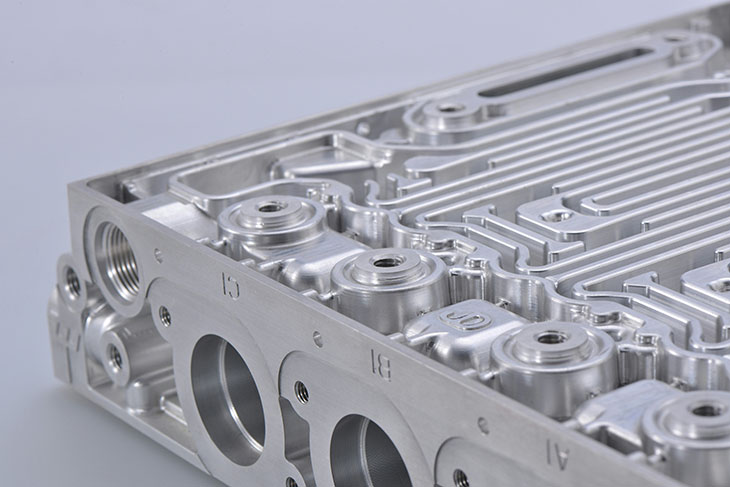

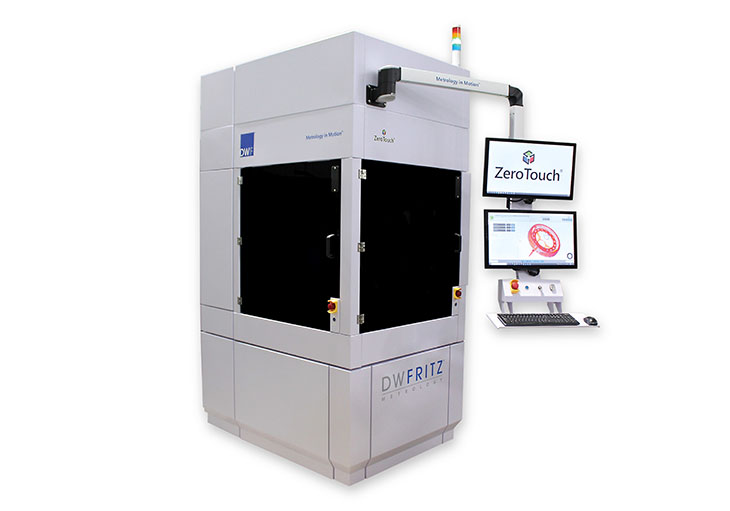

In sheet metal processing, ever greater flexibility of blanks is required for complex applications. Even with changing sheet thicknesses, demanding materials often have to be cut precisely and quickly. However, processing with separate cut-to-length and slitting lines is time-consuming and can only be carried out in several steps. For this reason, the b+s group has developed multi-blanking systems that combine both work steps in a single run. This means that even changing cut sizes can be carried out efficiently and with the highest quality in-house - without additional logistics costs. The systems enable a speed of up to 100 m/min with plug-in limits of over 1,000 N/mm² and material strengths of over 1,500 N/mm². Thanks to inspection measures, these are particularly suitable for sensitive surfaces such as stainless steel and alumium strips, which are used, for example, in metal components for white goods or in architecture for decorative elements. The new multi-blanking systems will be presented at this year's Blechexpo 2019.

"In order to avoid delays caused by external suppliers, many of our customers demand the integration of slitting shears into their cut-to-length lines in order to be able to carry out a further work step in-house," reports Thomas Baral, Managing Director of Burghardt + Schmidt GmbH. "Therefore, we have used the synergy effects of the individual companies of the b+s group to develop flexible systems for these high quality requirements". With the new multi-blanking systems, several precise and individual sheet metal blanks can be produced in one run. In addition, the high vertical range of manufacture offers greater independence with regard to the ever more rapidly changing market requirements.

Up to 5 strips can be cut lengthwise at 100 m/min.

The b+s group multi-blanking lines combine a cut-to-length line with a slitting line and are designed for sheets with a material width of up to 2,500 mm and a material thickness of 0.1 to 6.0 mm. Due to the existing leveling expertise of the world's first leveling machine manufacturer SCHNUTZ, they are recommended for strengths above 1,500 N/mm² and yield strengths above 1,000 N/mm². "Before the first cut, the coil is first leveled and only then cut into longitudinal strips," explains Baral. "These strips are then cut crosswise, resulting in up to five sheet blanks per segment in the desired length. Due to the large number of sheet blanks with small dimensions, the stacking and packaging area plays an important role. Therefore, the b+s group has paid attention to different stacking techniques such as a vacuum, magnetic tape or swing arm stacker.

In order to also meet high quality requirements, each system is individualized for the respective application. For example, the material data is a decisive criterion for the design of a multi-blanking line. "With our pre-sales service, a factory tour including personal consultation on site is an advantage, as the various requirements should be discussed intensively," says Baral. "The control and drive technology also plays a decisive role in high-quality plants, because this enables plants of this type to be designed for a plant speed of up to 100 m/min.". For this reason, the know-how of the b+s subsidiary DELTA Technik was also used for the automation of the plants in order to coordinate the mechanical with the electrical components.

The b+s group will present the new multi-blanking systems at this year's Blechexpo in Stuttgart at booth 8405 in hall 8. The managing directors of the b+s group companies will also be available to answer questions and provide concrete advice: Thomas Baral and Achim Kunz (Burghardt + Schmidt GmbH), Dr. Lutz-Stefan Henrich (Schnutz GmbH) and Frank Mehlich (DAA DELTA TECHNIK GmbH).

Further information on the Internet: www.b-s-germany.de, www.schnutz.com, www.deltatechnik.com

What: Blechexpo 2019

When: 05. to 08. November 2019

Where: Blechexpo trade fair

Hall 8, Booth 8405

Contact: Thomas Baral (Managing Director Burghardt + Schmidt),

Achim Kunz (Managing Director Burghardt + Schmidt),

Frank Mehlich (Managing Director DELTA Technik)