Filling by weight has many advantages compared to volumetric filling with flowmeters or other such devices. Weighing offers greater accuracy, ease of calibration, facilitation of statistical process control and better traceability. Weighing is the one universal technology that can be used regardless of material characteristics or container shape. A new Guideline from METTLER TOLEDO explains how to use various weighing technologies to improve filling operations.

Greifensee, Switzerland. September 25 2014 –A newFilling Guideline from METTLER TOLEDO addresses end users and machine builders, helping them to assess their current filling devices and evaluate alternative solutions. For end users, the Guideline provides a comprehensive overview of the most common filling technologies and terminology. Armed with this knowledge, end users can have a more productive and successful dialogue on an advanced level with potential vendors. The Guideline also provides advice for specifying professional request-for-quote documents.

In addition, the new guideline offers machine builders useful information on how to optimize the weighing performance of their filling machines. It explains the differences between speed and accuracy and explains other factors that influence filling accuracy.

The Filling Guideline includes sections that discuss:

- Finding the right filling method

- Filling machines, including bag fillers; bucket, drum and IBC fillers; and big-bag fillers

- More demanding applications

- Influence of fill material on accuracy

- Speed vs. accuracy

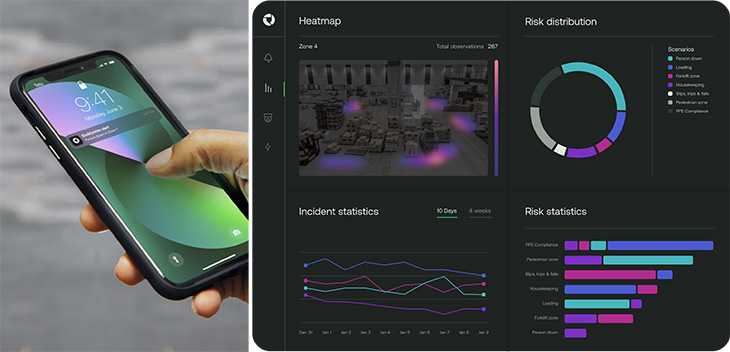

- Filling process and control

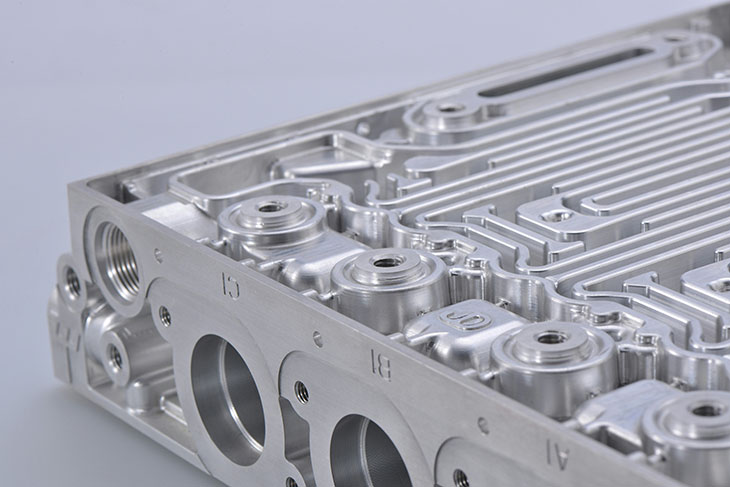

- Key filling machine components, including feeders, load-sensor technology and weighing terminals

- Weighing equipment for hazardous areas and

- Commercial and legal requirements.

To download the free Filling Guideline, visit www.mt.com/ind-large-volume-filling-guideline