Energy expenditure is intricately linked with the manufacturing industry. Throughout history, factories have been characterised by the black plumes of smoke bellowing from their giant chimneys, a visible emblem of what energy use looks like.

Undoubtedly, most manufacturers spend a fortune on their energy bills. After all, the business you run depends on the consistent operation of manufacturing equipment, meaning that the kilowatt count quickly racks up to something rather terrifying.

When it comes to saving energy, some business owners will automatically think of renewable energy sources such as solar and wind power, and tremble at the prospective sum that barges aggressively into the foreground.

But you don’t have to introduce a complete overhaul to start saving money on your energy expenditure. The Carbon Trust states that “manufacturers could cut energy bills by as much as 20 per cent just be implementing simple, inexpensive energy efficiency measures”.

It doesn’t have to cost you a fortune, but it can save you one.

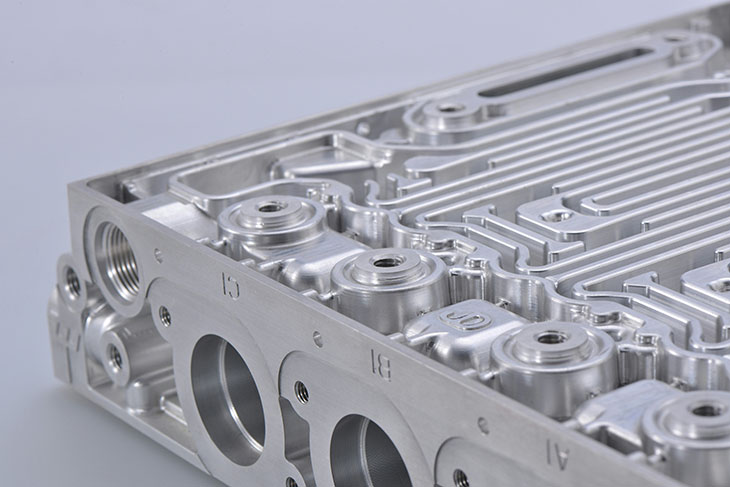

Motors

For a number of manufacturers, motors can account for a significant percentage of the total amount of energy your factory uses. The main reason motors costs so much money to operate is largely to do with the excess energy they end up using.

While some motors run at fixed speeds, making them particularly suited to applications when a constant speed output is required, around half of motors have a varying demand in processes that include moving air and liquids, and winding reels. Despite this fluctuation in velocity, these motors still use the same amount of energy, meaning that throughout the process a great deal of efficiency is lost.

A great way to counter this issue is to install a variable-speed drive (VSD), also know as a “frequency converter” or an “adjustable speed drive”. The purpose of a variable speed drive is to reduce the running costs of motors used for fans and pumps by adjusting the electrical supply to a motor to correspond with changes in the motor’s speed; for example, a 50 per cent reduction in speed would result in a 50 per cent reduction in energy expenditure. This prevents the motor from ever using more energy than it actually needs.

The monetary savings as a result are notable. According to British Gas, reducing a motor’s speed by 20 per cent with a VSD could see a drop in energy costs of up to 50 per cent. Essentially, manufacturers could be saving nearly half of what they currently spend on motor energy simply by attaching VSDs to applicable motors.

You can also invest into replacing conventional motors with higher efficiency motors (HEMs). Not only can the savings you make pay back the costs of buying a HEM within 24 months according to the Carbon Trust, but you might also be eligible for tax relief through Enhanced Capital Allowance (ECA), a government scheme designed to encourage energy-saving investments in businesses.

Refrigeration

Industrial-sized refrigeration units need to be checked frequently to ensure they are using energy as efficiently as possible, because a failure in these units can result in spoiled products as well as excessive energy bills.

Implement constant check-ups on the door seals to check they aren’t faulty. A faulty door seal will increase power consumption of a refrigeration unit by up to 11 per cent, and can hinder cooling functionality. Make it a priority to replace a door seal as soon as a fault is detected to make significant savings on energy costs.

You should also routinely clean the unit’s condensers. The Carbon Trust estimates that dirty condensers increase operating costs of a refrigeration unit by around 26 per cent on average. It’s an incredible saving when you consider the absence of any monetary investment needed on the company’s part.

Lighting

The majority of employees in the manufacturing sector will work throughout the day, so it’s important that employers capitalise on the natural light provided throughout the working day. Lighting up the factory floor can be as simple as opening any blinds that might otherwise be closed, or installing skylights in order to light areas of the building that may otherwise require artificial lighting.

Obviously, some manufacturing companies will operate throughout the night too, in which case artificial lighting is unavoidable. However, investing in sensor switches can lead to significant savings in the long run.

Installing daylight sensors ensures that lights are automatically switched off whenever there is enough natural light to properly illuminate the interior, and movement sensors mean that lights are only in full operation when there are employees working in the specified area.

Heating

Research from the Carbon Trust shows that 12 per cent of all energy consumed in manufacturing is actually used for heating buildings.

Saving energy on heating doesn’t necessarily mean having to compromise on comfortability during winter months. Instead, you can use less energy to get the same result if you invest in appropriate heating insulation throughout the workspace.

Insulating pipework and valves can cut heat loss by up to 90 per cent. In most cases, the cost is recouped within the first two years of the installation. Insulation should be applied to all valves and flanges where the pipe has a diameter greater than 50mm. Valves are best insulated using flexible jackets, allowing for easy removal and readjustment.

You should also tune up your boiler annually to get the most efficiency out of it. It could save you up to £800 every year, so having a boiler tuned is well worth the investment. The basic idea of boiler tuning is to optimise the amount of excess air within the tank; the ideal volume is around 4 per cent.

Energy Provider

The best way to make energy savings overall, however, is as simple as switching your energy provider. Regularly keep yourself updated with the best deal; just because the provider you deal with gave you a fantastic offer a year ago doesn’t necessarily mean they’re offering the best rates now.

The main lesson to learn is that there are opportunities to save money on your energy everywhere; it’s simply a matter of recognising those opportunities, and when you do, the benefits can be staggering.

Hazel Deller writes for Love Energy Savings. Business energy comparison specialists who lower business energy bills through their free & impartial services.