The Yawal Group is a modern producer of aluminum profiles, which plays one of the key roles in the industry. The Group, based in Poland, consists of companies: Final SA and Yawal SA. Final SA specializes in comprehensive aluminum extrusion services enriched with anodizing, painting and prefabrication services. The company’s systems reach markets all over Europe. Yawal SA offers architectural aluminum profile systems for the construction industry.

Especially for “Manufacturing Journal’’ magazine the interview was given by Mr. Tomasz Sęk – President of the Management Board of the Yawal Group.

Please tell me what were the beginnings of the Yawal Group and what were the most important moments in the history of its development?

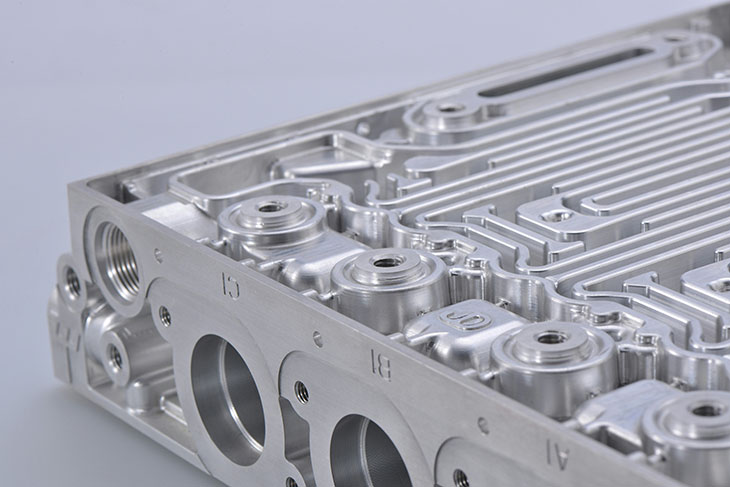

Exactly on September 14, 2020, have passed thirty years since the opening of the now defunct bar “Kaczorek” in Warsaw - the first implementation of PPH Yawal, which marks the symbolic start date of the enterprise. Initially, Yawal made structures based on systems imported from Western Europe. However, gaining knowledge and experience in this field allowed, three years after the company was opened, to produce the first Polish system of thermally insulated profiles. They have become a benchmark of quality on the market thanks to a very high level of energy efficiency at that time and a revolutionary modern design. It was a breakthrough moment for the company. Soon, several investments were completed, including a paint shop and a thermal bridge department. The production of system accessories was launched. In 1998, Yawal S.A. established the company Final S.A., and in 1999 the construction of the aluminum extrusion plant located in Dąbrowa Górnicza was completed. In the years 1999-2007, Final’s production plants were systematically expanded; three technological lines have been launched for extruding aluminum profiles (T1, T2, T3) and an anodizing plant. The rapidly growing market of aluminum profiles, and therefore the growing demand for Final products and Yawal systems, resulted in the launch of a wood-like painting production line at the Herby plant in 2009, and a vertical powder coating line in May 2010. In 2011, a mechanical processing department and a high-bay warehouse were opened. From the producer of aluminum joinery, Yawal transformed into a system enterprise.

The core business of the Yawal group is the production of aluminum profiles and their processing. Can you tell us more about the services and products offered?

Both companies belonging to the Group have a strong impact on the industries in which they specialize. At Final S.A. is a modern pressing plant of aluminum profiles. The company’s products are widely used in transport (e.g. for the production of truck sides), interior fittings (handrails, balustrades, roller shutters and shutters), infrastructure (acoustic screens, masts and antennas) and in construction. Observing the market situation and knowing how much the automotive industry had suffered in the pandemic era, we had to look for new markets for our extruded profiles. We are a very dynamic and flexible organization, in which we can make decisions de facto overnight, if the need arises. So, we designed and manufactured a complete system for photovoltaic panels. Steel structures are used in large photovoltaic farms, but already in installations on single-family houses, the structures are usually made of aluminum. The idea turned out to be a bull’s eye, which we can see in increases of several dozen percent year on year. When we started selling to producers and dealers in the photovoltaic sector in 2019, the number of profiles produced, in terms of tonnage, was several hundred tons. In 2020, sales oscillated around 2,000. tone. Today, the sale of profiles to the photovoltaic sector accounts for almost 10 percent of the production of our pressing plants. In the case of the construction industry, Final is a supplier of aluminum profiles for our second company, Yawal S.A., which uses them to design systems for the construction of extremely durable, warm, and tight windows, doors and facades. Yawal not only responds to the needs of aluminum joinery producers, but also creates trends and solutions that have not been used on the market so far. In 2020, we started the production of a system of large-size sliding doors, the frames of which are completely hidden in the walls of the building. The Moreview system, because this is what we are talking about, was not the first solution of this type, but it was certainly the most thoughtful and refined premiere of 2020, which introduced functionalities unheard of by other system providers. Importantly, Yawal is not only a distributor of architectural aluminum profile systems, it acts as a partner for its clients that also guarantees technical or training support.

Who do you address your offer to and what distinguishes it from the competition?

We focus both on manufacturers and architects, but also on end customers, and we have been working closely with them for thirty years. It is the exchange of experiences that allows us to adapt to the rapidly changing market conditions. One of Yawal’s competitive advantages is the concentration of the entire production process in the hands of our capital group. Thanks to Final, we are not dependent on deliveries from external presses, which makes us more flexible than other system suppliers. We have three presses for stamping profiles with a total production capacity of 26,000 tons per year and a powder coating shop with a maximum capacity of 1000 m² / h . Technical solutions, innovation, customer focus and highly trained workforce are important aspects of our competitive advantage.

Does the Yawal Group fit the Industry 4.0 trend and invest in the latest technologies and solutions?

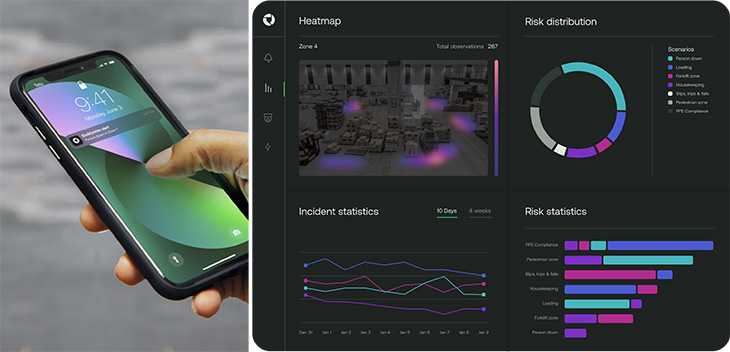

The 21st century is the time of automation, robotization and the use of modern technologies wherever it is possible to connect the world of people and machines. One of the success factors are well-designed processes, including the purchasing process, which is why in 2020 the management board of the Yawal Group made a decision to digitize the purchasing process in both its companies: Yawal S.A. and Final S.A. The task was entrusted to the company Open Nexus Sp. z o.o., which carried out this digital transformation through its proprietary tool called platformazakupowa.pl. Last year, we also established cooperation with Orgadata and implemented the LogiKal software. This software allows you to support the automation of joinery production, saving up to 50% of work time. In our activities, we assist our business partners at every stage of their operation, from the preparation of offers, through production, marketing, and sales to investors. A company that does not have a target, it is not known where it is going. This is the subject of our strategic discussion and we obviously set ourselves some priorities. They are not necessarily related to market position in terms of sales volume or market share. Of course, we also think about it, but we want Yawal to specialize in specific products and specific markets. Each company must find its place on the market and we want to find such a place through pro-ecological activities and specializing in specific product groups. I would not like to reveal details about the directions of our development, but the digitization and transformation of customer service in the broad sense is a very important aspect for us. We see a lot of potential here and we want to orientate ourselves in this way. It is about customer service before, during and after the sale, not only in a conventional way, but also with the use of online tools.

The quality of the products and services offered is your priority, therefore you cooperate only with proven partners. Would you like to highlight any of the companies - your most important suppliers, subcontractors, or partners?

As I mentioned before, quality, and environmental protection are now a very important issue not only in the construction industry, but in fact in every sector of the economy. For this reason, we strive to use environmentally friendly and even - if possible - biodegradable materials and substitutes for the production of our aluminum profiles and systems. We analyze and verify our systems in terms of the components used for their production: gaskets, spacers, handles and paints. Each of the elements selected in the near future will must have environmental certificates or be made of biodegradable materials. In this regard, we cooperate with market leaders such as IGP Pulvertechnik, ROTO Frank, Wala, Sobinco, Geze, Fapim, Jotun, Tiger, HAUTAU and many others.

The received certificates and awards are the confirmation of the high quality of the company’s operation and the products offered. What certificates, awards and titles can you boast of?

Among the many important certificates used by the companies belonging to our Group, the quality management system ISO 9001: 2015 and the environmental management system ISO 14001: 2015 should certainly be mentioned. The quality of our anodic coatings is confirmed by the QUALANOD mark, and the varnished coatings by the QUALICOAT certificate. For 30 years of operation of Yawal S.A. there were also many industry awards for our architectural aluminum profile systems and the company itself, including the following awards: “Top Builder”, “Top Design Award”, “Innowacyjne Rozwiązania Branży Stolarki”, “Budowlana Marka Roku” or “Gazele Biznesu”.

The Yawal Group is one of the largest aluminum groups in Central and Eastern Europe. Please tell me what is the most important in your business? What is the strategic potential of your company and the key to its success?

What is most important to us is what our clients expect, they set our development directions. It is “customer-centricity” that is our guideline. Our goal is not to observe or imitate our competition, we have ambitions to follow our own path, determined by the expectations of our customers. Considering the dynamically developing market of aluminum joinery, this place on the market is for everyone. It is important to define your role, for example, by specializing in one or two product groups. At the Yawal Group, we have the ability to design, emboss, paint, anodize, bridge and de facto produce the end product throughout the entire supply chain, which all our competitors cannot offer. This is our big advantage and we take advantage of it. In addition, technical solutions, innovation, customer focus are important aspects of our competitive advantage.