They have come a long way – from traditional artisans to a multinational corporation – and yet preserved their own identity. They began by making jewellery and shoe springs. Today they cater for the largest cars and trucks producers worldwide.

A business that is family-owned and has their branches in Germany, Spain, Poland, Hungary Mexico and China? However poles apart these may seem, GEDIA knows how to make them work. “Our core value is respect. Our mission statement: together– one step ahead,” explains Mr Andrzej Marcinek, GEDIA Poland Assembly Managing Director.

Come a Long Way

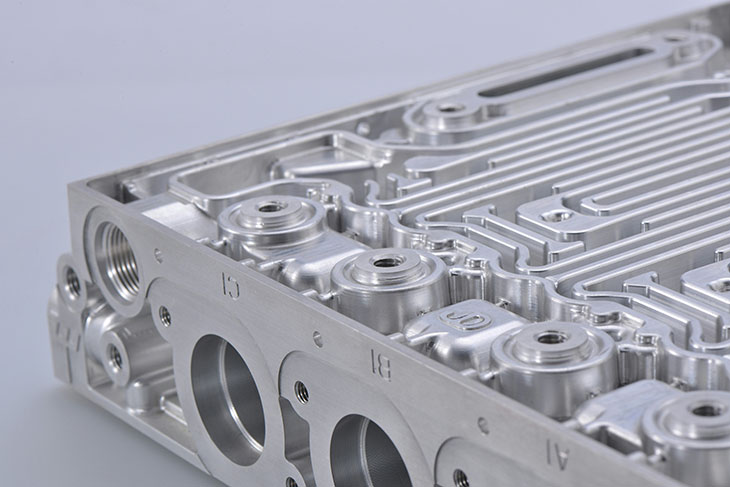

For more than a century now, GEDIA has been maintaining the best traditions of German craftsmanship. Its success story began in 1910, when two brothers, Anselm and Ferdinand Dingerkus, established the family-run Gebrüder Dingerkus company in Attendorn, Germany. With its initial focus on jewellery, the business soon expanded in scope with sheet handles for enamelware dishes and plastic handles. As for the latter, GEDIA’s factory could turn out even 10 million such handles every year. A jeweller’s precision and mass production: these assets could hardly pass unnoticed in the industry that relied and still relies on top quality metal sheets. Hence, in 1955, GEDIA launched the production of pressed, stamped and drawn parts, especially for the automotive industry. The years that followed brought further improvements in the technology. It is the nineties that proved truly pivotal in this respect, when first transfer presses with a pressure capacity of up to 2000 tonnes and spot welding robots for large components were introduced (currently group uses welding systems with approx. 200 such robots). There is one more reason why the nineties proved so important, however. It was also then that GEDIA expanded overseas. Its first investment abroad was completed in Nowa Sól, Poland. Nowadays the group boasts branches in Tata, Hungary; Sta. Margarita, Spain; Puebla Mexico and Nanjing, China. As befits a traditional, family-owned business, the entire group is still run from Attendorn, where technology, logistics and tooling corporate centres are located, too. “Each of our branches is equally important. For this reason, we act as a group and support sustainable development,” emphasises Mr Andrzej Marcinek, GEDIA Poland Assembly Managing Director.

Facts and Figures

GEDIA’s business capacity is measured in facts, not in words. The group boasts five production plants all over the world and generates an annual turnover of more 340 million EUR. This tremendous success would not be possible if it was not for the workers: more than 2400 employed directly by the group plus those hired by GEDIA’s joint-venture in Mexico. GEDIA has also become a trusted associate in the field of R&D. As a first choice provider it cooperates with Audi, BMW, Citroen, Daimler, Fiat, Ford, General Motors, Karmann, Porsche, PSA Peugeot, Scania, Skoda, Suzuki, Volkswagen and Volvo. Their greatest pride? “We boast competent and well-motivated people and the high quality of production,” says GEDIA Poland Assembly Managing Director. “We have achieved this outstanding level of quality thanks to modern, automated production processes managed and supported by our responsible and dedicated crew. This in turn results in a fruitful and open co-operation with the Clients. Our chief assets are experience, timely delivery and flexibility. The latter seems especially in demand as the memory of the recent crisis is still alive in the industry.”

Gedia in Poland

Satisfied Customers are those who keep coming back, even with the crisis still taking its toll. GEDIA Poland can boast exactly such Clients. “This year looks quite promising and we have already received a substantial number of orders. Hopefully, this upward trend will continue in the months to come,” adds Mr Marcinek. When entering the Polish market, the business counted only 27 employees. However, the company has been growing at a dizzying pace and has changed a lot since then. There are already two GEDIA branches in Poland: GEDIA Poland located nearby the city centre and GEDIA Poland Assembly, located in the Kostrzyń-Słubice Special Economic Zone. The former has been in operation since 1998 and is now employing about 1000 people, who press and assembly components for the leading brands of automotive industry. The latter has been in business for 2 years only and yet managed to create jobs for about 200 workers, 54 of which are women, a fact to be noted in the automotive industry. “When we decided to develop a new factory floor, we did so with one aim: despite the crisis, it had to be built according to a strict schedule so that the company would be able to deliver components for a new model on time. Hence, around 18 months elapsed between initial groundwork and a grand opening,” remarks GEDIA Poland Assembly Managing Director. GEDIA Poland Assembly specialises exclusively in assembling complete longitudinals to Astra IV passenger vehicles. The longitudinal is a spatially complex chassis component and, as such, requires state-of-the-art technologies. “We have such technologies,” emphasises Mr Marcinek. “Our innovative solutions helped us become a first choice supplier for General Motors. We have also made our mark in the field of research and development.”

Local Content

With two factories in Nowa Sól, GEDIA Group is still investing in the area. GEDIA Poland has recently started the construction of the new pressing facilities; these are going to be fitted with production lines specialised in the pressing and forming of car components and accessories. GEDIA Poland Assembly also plans to expand the production. It should be emphasised that the business is priming the pump in the area where it already employs more than 1200 people. “Everybody in Nowa Sól knows who GEDIA is and where our facilities are. We are the largest employer in the area. We do our best to live up to the excellent reputation we have there,” points out GEDIA Poland Assembly Managing Director. “That’s why we spare no expense on charity and help those in need. We also support local schools and fire guard, and subsidise the local football team, too.”

Motivation and Respect

GEDIA attaches great importance to a living and breathing corporate culture, characterised by mutual respect and active support. The business actively supports the competence development of their employees and improves their motivation, self-confidence and capability. The basic tenets of GEDIA’s corporate philosophy? The group acts as a whole and, as such, strives for leadership in selected areas of sheet forming and joining technology. This common objective ensures the company’s recognition. What makes the business valuable is trust, readiness to change and responsibility. For GEDIA, the integration of different kind of employees, regardless of their nationality, gender, religion or personal skills is a matter of course. “Our core value is respect. Our mission statement is: together – one step ahead. This means team work and strong customer focus. However, we also support independent thinking and proactive attitude. Active motivation and development of all the employees plays a pivotal role in our success. That’s why we are after open dialogue, clear goals and that kind of management which is both resolute and lean. These are intrinsic parts of our corporate culture,” adds Mr Marcinek.

Together - One Step Ahead

As a worldwide operating family-owned company GEDIA strives to maintain a market leading position in high-tech quality structural parts and assemblies for automotive body construction. Its main priority as a group is to secure Customer satisfaction and confidence in its products and services. For this reason, the business concentrates on a constructive and long-term cooperation with its business partners all over the world. The group is also striving for sustainable growth. Success-oriented and competitive, the company is equally aware of its social and ecological responsibility. “As a group, we know how important it is to protect the environment. That’s why we are committed to taking a responsible approach to natural resources. The better technology we implement, the lighter the cars will be. This means lower fuel consumption, of course,” elaborates Mr Marcinek. “As GEDIA Poland Assembly, we have introduced a strict waste-disposal policy and developed energy-efficient facilities. In doing so, we have followed the detailed and trusted guidelines provided by our mother-company. These efforts have been duly appreciated. We won the Polish Automotive Chamber Award for the Best Automotive Investment in 2009. We were also granted ISO 14001 Environmental Management Standards Certificate in May 2010. We did equally well in the check conducted by the Environmental Protection Inspector in September the same year.”

Reliable and Proactive

“It pays to be our Client,” emphasises GEDIA Poland Assembly Managing Director. “We make a trusted associate and have a long and proven track record. We have come a long way since 1910: from traditional artisans to a multinational modern corporation. We are not an ordinary provider of products and services. Not only do we complete the projects but also develop and readjust them in the process. We are sought after in the industry for being reliable and proactive.” At present GEDIA is developing a brand new hot pressing technology. Even though nearly 80 per cent of the cars are manufactured with traditional, cold pressing solutions, the future belongs to new lighter counterpart. Thanks to this new sheet forming method cars will be lighter, safer and more efficient. “Gedia is heading in the right direction. We have also specialized and reliable team ready to co-operate with all the clients in the planning of new future projects, demanding modern technological solutions. Having clear roots, long tradition and modern technologies, we are the company with great potential for the future. Innovation aus Tradition this is our motto.” recaps Mr Marcinek.